Know-How

Screws and Pellets: One Size Does Not Fit All

Screw design, pellet type/size and material behavior are all critical issues to consider to deliver uniform melt to the mold.

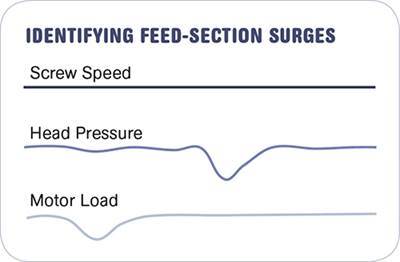

Read MoreOverfeeding Can Cause Surges, Too

Surging can be caused by feed restrictions, as covered in another column, and also by over-feeding or under-melting, discussed here.

Read MoreKnow the Three F’s Of Profile Tooling Design

Designing an extrusion profile and ultimately the die design and sizing equipment cannot be executed successfully without a full understanding of the customer鈥檚 quality expectations or specifications.

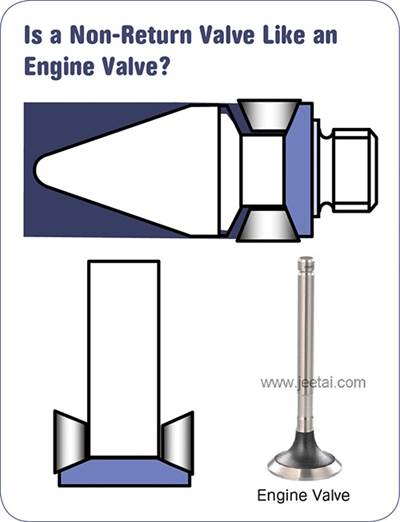

Read MoreWhy Non-Return Valves Leak

We all recognize that the non-return valve is a problem. The question is where is the research to figure out how to correct this so we have a better shot at making more consistent parts

Read MoreSolving Feed-Related Surging

Understanding the causes of surging can help troubleshoot and correct it.

Read MoreCreate a Maintenance Work (Bench) Cell

Get better results by improving the organization of your mold-maintenance operation.

Read MoreMaking a Part for the First Time? Here’s How to Get Going

First time parison programming for a new part can be lengthy and tedious. Here's some advice on making the process a bit easier

Read MorePay Attention to Your Nozzle Body & Tip

These are overlooked components that can cost you thousands.

Read MoreExtrusion: A Roll Is a Roll Is a Roll?

Chill rolls may looks simple and shiny, but they play a critical part in cooling and polishing film and sheet and are not all the same.

Read More