Hot Runners for Plastics Production

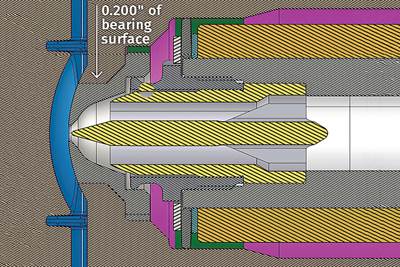

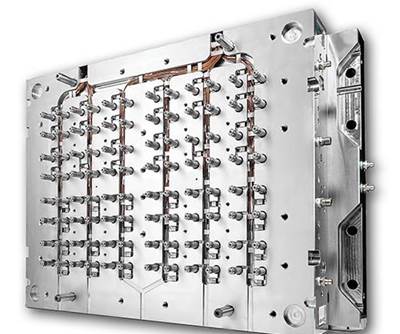

A hot runner system is an assembly of heated components—hot halves, nozzles and gates and—that inject plastic into the cavities of an injection mold. The system usually includes a heated manifold and a number of heated nozzles.

ESSENTIAL READING

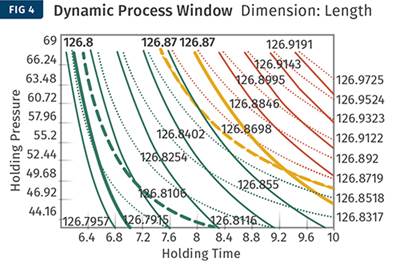

VIEW ALLOptimizing Pack & Hold Times for Hot-Runner & Valve-Gated Molds

Using scientific procedures will help you put an end to all that time-consuming trial and error. Part 1 of 2.

Read MoreHow to Start a Hot-Runner Mold That Has No Tip Insulators

Here's a method to assist with efficient dark-to-light color changes on hot-runner systems that are hot-tipped.

Read MoreHot Runners: How to Maintain Heaters, Thermocouples, and Controls

I conclude this three-part examination of real-world problems and solutions involving hot runners by focusing on heaters, thermocouples, and controls. Part 3 of 3.

Read MoreHot Runners: Truths. Myths, Overlooked Areas: Part 2

Here’s a view from the trenches of a tooling manager who, over 30 years, has experienced the joys and pains of using virtually every type of hot runner on the market. Part 2.

Read MoreHow to Optimize Pack & Hold Times for Hot-Runner & Valve-Gated Molds

Applying a scientific method to what is typically a trial-and-error process. Part 2 of 2.

Read MoreHot Runners: A View from the Bottom Up

Addressing hot-runner benefits, improvements, and everyday issues from the perspective of decades of experience with probably every brand on the market. Part 1 of 2.

Read MoreLatest Hot Runners News And Updates

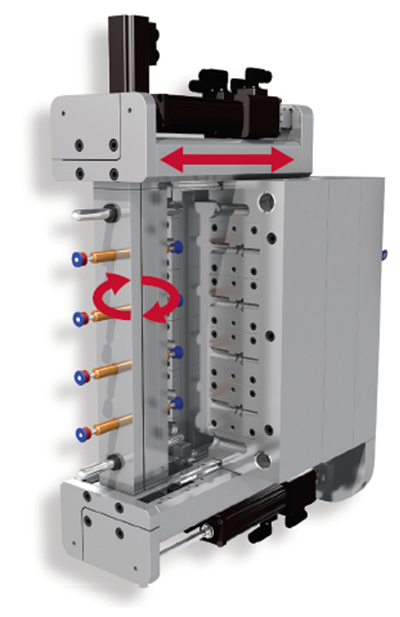

PET Preform Hot Runner System Reduces Stack Height

Mold-Masters has cut the stack height of its PET-Series hot runner system from 300 mm to 260 mm, while maintaining a 3-plate design and the advantages therein.

Read MoreNew Hot Runner Temperature Control

Oerlikon HRSflow’s T-Flow HRS control has launched with three models that are configurable to multiples of six zones.

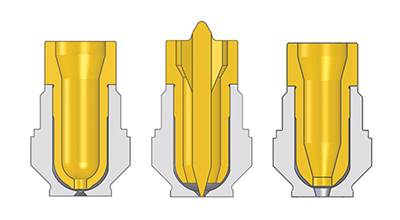

Read More3D Printed Hot Runner Nozzles, Pressure Pads Provide Reliable Temperature Handling

NPE2024: Witosa GmbH, through its distributor DMS, brings the Monolith hot runner nozzle and hardened steel Energy Blocker to the U.S., enabling the reduction in time, costs and improvements in product quality.

Read MorePlug-and-Play Modular Hot Runner Controller

NPE2024: Spark Industries’ patent-pending MOD24 hot runner controller offers unlimited plug-and-play of 6-zone hot runner control modules.

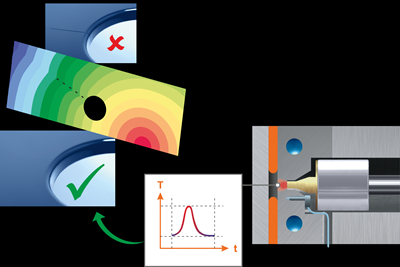

Read MoreMovable Tempering Stamp Can Eliminate Surface Defects

NPE2024: Incoe says Heat-Inject Technology introduces localized heat to remove weld or knit lines, or help melt flow into hinges, thin walls, delicate geometries or microstructures.

Read MoreHot Runner Temperature and Mold Motion Controllers Debut

NPE2024: Hot runner systems, temperature and motion controllers, an auxiliary injection unit and a gate seal are among Mold-Masters’ show features.

Read MoreFeatured Posts

Hasco Marks a Century in Mold Components, Mold Bases and Hot Runners with Cake and New Technologies

NPE2024: Cake, drinks and the unveiling of a new North American website providing online ordering in the U.S. and Canada for the first time are just some of the things happening at Hasco’s booth as it brings its year-long centennial celebration to Orlando.

Read MoreHow to Start a Hot-Runner Mold That Has No Tip Insulators

Here's a method to assist with efficient dark-to-light color changes on hot-runner systems that are hot-tipped.

Read MoreHot Runners: How to Maintain Heaters, Thermocouples, and Controls

I conclude this three-part examination of real-world problems and solutions involving hot runners by focusing on heaters, thermocouples, and controls. Part 3 of 3.

Read MoreHot Runners: Truths. Myths, Overlooked Areas: Part 2

Here’s a view from the trenches of a tooling manager who, over 30 years, has experienced the joys and pains of using virtually every type of hot runner on the market. Part 2.

Read MoreHow to Optimize Pack & Hold Times for Hot-Runner & Valve-Gated Molds

Applying a scientific method to what is typically a trial-and-error process. Part 2 of 2.

Read More