Plastics Use in the Packaging Industry

Plastics are used to manufacture flexible packaging and rigid packaging in applications like caps, closures, bottles, film, and sheet.

ESSENTIAL READING

VIEW ALLHow to Extrusion Blow Mold PHA/PLA Blends

You need to pay attention to the inherent characteristics of biopolymers PHA/PLA materials when setting process parameters to realize better and more consistent outcomes.

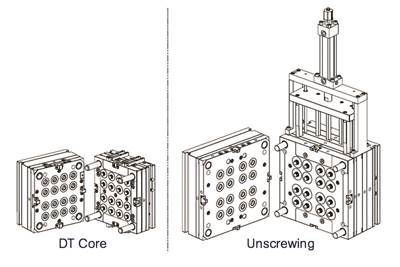

Read MoreBest Methods of Molding Undercuts

Producing plastics parts with undercuts presents distinct challenges for molders.

Read MoreSolve Four Common Problems in PET Stretch-Blow Molding

Here’s a quick guide to fixing four nettlesome problems in processing PET bottles.

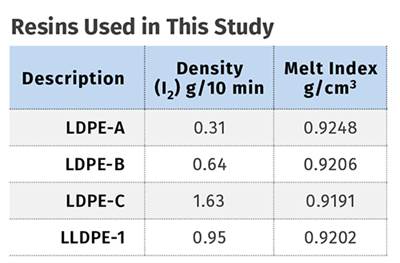

Read MoreFormulating LLDPE/LDPE Blends For Abuse–Resistant Blown Film

A new study shows how the type and amount of LDPE in blends with LLDPE affect the processing and strength/toughness properties of blown film. Data are shown for both LDPE-rich and LLDPE-rich blends.

Read MoreProtolabs Addresses How to Survive a Pandemic with Digital Manufacturing

Protolabs survey results examine product development and the supply chain.

Read MoreWhat Plastics Processors Need to Know about Tax Reform and Equipment Acquisition

The Tax Cuts and Jobs Act of 2018 (TCJA) is positioning plastics processors for more growth and profitability following the most recent Plastics Processing Index showing the best quarter since 2013 when the index began.

Read MoreLatest Packaging News And Updates

Ultimaker S6 3D Printer for Engineers, Manufacturing Teams and Maintenance Crews

New generation delivers faster print speeds.

Read MoreCobot Automates Label Reel Loading for High-Volume PET Beverage Bottles

Sidel’s new CoboREEL system uses a cobot to automate a shift’s worth of label reel loading.

Read MoreAvantium and Bottle Collective in Partnership to Launch PEF Fiber Bottles

Partnership expects PEF to provide higher strength and improved barrier properties.

Read MoreUltralight PET Preform Design

The Factor 101 design created by KHS and Husky uses just 5.89 g of material to hold 591 mL of product — equivalent to a 20-ounce water bottle.

Read MorePrecision Concepts Buys Meredith-Springfield

Latest acquisition by this diversified producer of rigid packaging is a Northeast leader in technical blow molding.

Read MoreUniloy Celebrates 75th Anniversary

America’s first and oldest blow molding machine supplier marks a milestone.

Read MoreFeatured Posts

Blow Molder’s Packing & Shipping Upgrades Save Bottle Customer Over $90,000

Currier Plastics’ continuous improvement program brought new efficiencies in processing, packaging and shipping for the molder and for a bottle customer.

Read MoreThe Recycling Collaboration That Is Making Circular Film a Reality

Nova Chemicals and Novolex are commissioning a large mechanical recycling facility for film to film.

WatchThe Middle Way, Dissolution Recycling Technologies Leave the Polymer Intact

Alternative approaches can produce high yield and high purity with reduced energy demand.

Read MoreIs There a Better Way to Heat PET Preforms for Stretch-Blow Molding?

Is near-infrared (NIR) heating better, faster and more energy efficient? So far, only two machi