Injection Molding

In injection molding, material is fed through a hopper into a barrel where a reciprocating screw mixes and melts the material then injects it into a mold.

Narrow Your Injection Molding Search

ESSENTIAL READING

VIEW ALLAIM Institute Continues to Grow Plastics Education and Training on 10th Anniversary

The AIM institute was created in response to the rising need for skilled injection molding professionals, providing individuals with a fundamental understanding of plastic rheology and plastic flow through a mold.

Read MoreBulk, Solid and Melt Density: How to Calculate These Values and Why They Matter — Part 2 of 2

Understanding and calculating solid density and melt density will help molders with everything from material and machine selection to determining piece part costs.

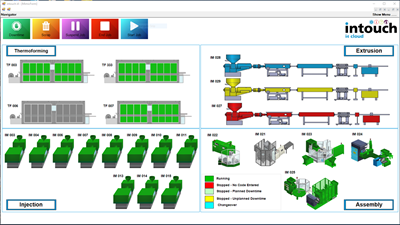

Read MoreProcess Monitoring or Production Monitoring — Why Not Both?

Molders looking to both monitor an injection molding process effectively and manage production can definitely do both with tools available today, but the question is how best to tackle these twin challenges.

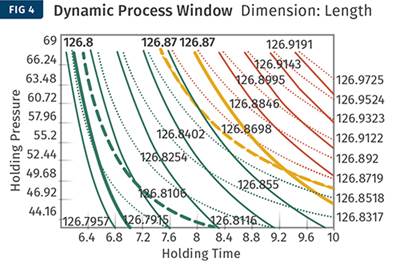

Read MoreOptimizing Pack & Hold Times for Hot-Runner & Valve-Gated Molds

Using scientific procedures will help you put an end to all that time-consuming trial and error. Part 1 of 2.

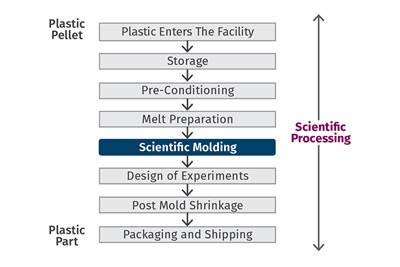

Read MoreA Systematic Approach to Process Development

The path to a no-baby-sitting injection molding process is paved with data and can be found by following certain steps.

Read MoreThree Key Decisions for an Optimal Ejection System

When determining the best ejection option for a tool, molders must consider the ejector’s surface area, location and style.

Read MoreLatest Injection Molding News And Updates

Yizumi Rebrands, Dropping HPM Name

The maker of injection molding and die-casting machines will now be Yizumi, not Yizumi-HPM, unifying its global identity and worldwide growth strategy.

Read MoreNetstal To Introduce Next-Generation All-Electric Elion Injection Molding Machines at K 2025

Netstal will introduce the Elion MED in Düsseldorf with a smaller footprint and greater energy efficiency.

Read MoreNorth American Plastics Shipments Drop for Second-Straight Quarter

The Plastics Industry Association’s Committee on Equipment Statistics (CES) showed declines on a quarterly and year-over-year basis in the first quarter.

Read MoreAdvanced Valve Gate Solution for Multicavity Line Saves Time, Optimizes Performance

Oerlikon HRSflow highlights an advancement for its Multiflow HRS multicavity line, the EYEgate HRS, a valve gate hot runner system solution.

Read MoreLow-Volume Dryer for Engineering Resins

Target markets are low-volume, high-precision specialty applications in automotive as well as in electronics, connectors and technical molding.

Read MoreLSR Cold Runner Deploys Servo-Actuated Needles for Smart Operation

Elmet says the patent-pending SMARTshot I cold runner measurement and control concept uses servo-actuated nozzle needles to enable automatic startup without additional sensors.

Read MoreFeatured Posts

Pursuing Paperless: Injection Molders Who Have Embraced Digitization

Read about injection molders who have shifted everything from quality control and scheduling to production and process monitoring to the digital realm.

Read MoreKeeping Process Water Cool and Efficiency High in the Desert

Rehrig Pacific turned to Process Cooling Systems to create a high-efficiency plantwide process-cooling system for its newest injection molding facility outside of Phoenix.

Read MoreSkipping the Pellet for Efficient Recycling in Molded Engineering Plastics Applications

AGS Technology leverages deep experience in molding with recycled engineering materials for automotive and heavy equipment parts.

Read MoreMPM’s Second Act: Keeping Injection Molding, Moldmaking in the Midwest

Larry Austin’s 35 years at a highly successful injection molding company inform much of what he does and doesn’t want in his second act in plastics owning an injection molding company.

Read MoreWhen Injection Molding Simulation Can Be a Great Troubleshooting Tool

Injection molding simulation can serve as a powerful tool not just for design but also for ongoing production optimization.

Read MoreDigital Manufacturing: Two Medical Molders Embrace Industry 4.0

‘Digitalization’ and ‘connectivity’ are loaded terms—shorthand for a whole new way of doing 大象传媒. It can’t be accomplished in one go. But two Midwest molders in the sensitive medical field are already feeling the benefits of their initial steps in that direction.

Read MoreFAQ: Injection Molding

Plastic injection molding is a cyclical manufacturing process that allows for cost-efficient production of a mass number of identical parts made from either thermoplastic or thermoset materials.

Cushion values in injection molding ultimately are an indication of a part’s quality, especially its dimensions. A consistent cushion will create consistent part dimensions.

It is important to determine which type of bubble your part has, and what the root cause might be. Determining bubble type will allow you to pinpoint the source and determine your next course of action to eliminate the problem.

Most molders are still relying on “general-purpose” screw designs that go back 30 years. With all of the technical improvements that have been made on machines over that time, nothing has been done to improve melt uniformity. We still use “general-purpose” (GP) screws, which well-known screw designer Bob Dray wisely has called “no-purpose” screws. That is they do not melt plastic uniformly. Processing with a uniformly melted plastic would seem like a high priority, but it has seen little if any attention.

Injection Molding Supplier Categories

- Thermoformers

- Platens

- Extrusion Blow Molding Machines

- Pre-expanders, Polystyrene Bead

- Mold-Cleaning Equipment & Chemicals

- Trimmers, Deflashers for Blow Molding

- Stretch-Blow Molding Machines

- Injection Blow Molding Machines

- Dip-Blow or Compression-blow Molding Machines

- Injection Molding Nozzles

- Parison Programmers

- Presses, Polystyrene Bead

- Spray Coating Systems (for Bottles)

- Inserts

- Accumulators (Melt)

- Structural Foam Machines (for Thermoplastics)

- Injection Molding Non-return Valves