Additive Manufacturing with Plastics

Additive manufacturing or 3D printing in the plastics industry involves the creation of components without dies or tooling—or the fabrication of tooling itself—for use in prototyping, bridge production, or short-run production. Common types include stereolithography (SLA), selective laser sintering (SLS), fused deposition modeling (FDM), and digital light process (DLP). Learn more at What Is Additive Manufacturing?

ESSENTIAL READING

VIEW ALL5 Big Themes in Additive Manufacturing at Formnext Forum: Austin

As manufacturing advances with additive, the advance increasingly emphasizes these five themes.

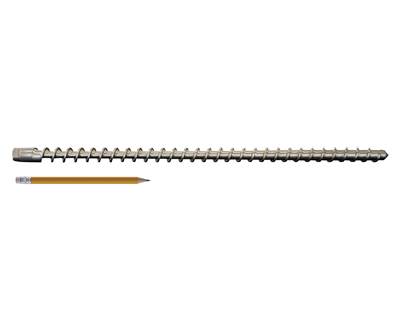

Read MoreWhat You Should Know About Miniature Extrusion Screws

Very small screws have become more common with the growth of additive manufacturing. Designing such screws requires balancing their output requirements with their torque strength.

Read MoreLatest Additive Manufacturing News And Updates

Xenia 3DF Materials for FFF Printing

Xenia is introducing new filament materials for fused filament fabrication.

Read MoreJuggerbot P3-44 Astra Enables Large Format Printing With PVC

Process controls and safety systems specifically tailored for industrial printing with PVC.

Read More3Devo Filament Maker Two Enhances Extrusion Control

The machine includes an upgraded screw drive, monitoring and user interface for enhanced filament production.

Read MoreFormlabs Form 4L and Form 4BL Print Expand 3D Print Volumes

Formlabs 4L and 4BL offer high sprint speeds and nearly 5 times the volume.

Read MoreInsight Polymers & Compounding Unveils New Conductive Products Line

The new conductive products line will also be produced for injection molding and extrusion.

Read MoreXact Metal Partners with PanOptimization to Incorporate Simulation and Optimization in Additive Manufacturing

Thermomechanical simulations will enable identification and correction of build issues prior to 3D printing.

Read MoreFeatured Posts

BMW Group Vehicle to Adopt 3D Printed Center Console

A vehicle coming to market in 2027 will include a center console carrier manufactured through polymer robot-based large-format additive manufacturing (LFAM).

Read More3D Printed Spine Implants Made From PEEK Now in Production

Medical device manufacturer Curiteva is producing two families of spinal implants using a proprietary process for 3D printing porous polyether ether ketone (PEEK).

Read MoreThe Connector Conundrum: 3D Printed Mold Tooling’s Role in Innovation

ReelView Fishing faced an electronics obstacle in the development of its new technology for underwater video. Additive manufacturing for moldmaking allowed for the speed necessary to iterate to a solution. How inventors and invention will benefit from new ways of obtaining production-ready tooling.

Read More7 Takeaways on 3D Printing As a Pathway to Polymer’s Future

The Cleveland section of SPE hosted “Additive Manufacturing: Printing the Path for the Future” on October 17, 2024. Speakers signaled where AM is and where it is headed with session topics ranging from pellet-based 3D printing to qualification and commercialization of additively manufactured products.

Read MoreAdditive Technologies for Injection Mold Tooling Ride Tailwinds

NPE2024: Lowering barriers to additive manufacturing adoption in toolmaking.

WatchNPE 2024: Additive Manufacturing Assisting, Advancing Plastics Processing

Exhibitors and presenters at the plastics show emphasized 3D printing as a complement and aid to more traditional production processes.

Read MoreFAQ: Additive Manufacturing

Do I Need Additive Manufacturing Skills in My Business?

Essentium announced the third in a series of findings from independent global research on the current and future use of industrial 3D printing. The survey found an increasing need for more education, skills, and training across manufacturers’ organizations. Even as the industry moves towards large-scale AM, 28% of manufacturers reported their personnel lacked AM skills.

In recent years, it has become apparent that additive manufacturing—aka 3D printing—is destined to have a role in plastics mold making, owing to cost and lead-time advantages over conventional subtractive manufacturing—CNC machining—and unique abilities to produce complex internal tooling geometries such as conformal cooling channels.

Additive Manufacturing Supplier Categories

- Additive Manufacturing (3D Printing/Prototyping Materials)

- Automation/Systems Integration

- Drive Controls

- Recording Instruments

- Troubleshooting, Problem Solving Systems

- Recycled/Reprocessed Materials - Ground Flake

- Machining, Drilling, Routing Equipment

- Machining, Routing Software

- Materials Formulating Systems

- SPC, SQC Systems

- Product & Tool Design, Analysis Software (CAD/CAM/CAE)

- Liquid Resin Filtration Materials, Equipment

- Maintenance Management Systems

- Cutting Tools (General)

- Core Materials

- Scheduling, MRP, Production & Inventory Management Systems

- Ultrasonic Cutters

- Job Estimating Software

- ISO 9000 Software

- Recycled/Reprocessed Materials - Bale or Bulk

- Particle Screeners, Classifiers, Separators

- Prototyping Services

- Stock Shapes - Film, Rod, Tube, Sheet

- Dewpoint Monitors/Moisture Analyzers

- Fasteners

- Flow Monitoring/Control Devices (for Liquids)

- Clamps & Fixturing Devices

- Fluid-jet Cutting Systems

- Plastics Processing - Design, Manufacturing, Purchasing

- Pressure Controllers, Monitors

- Controllers, Monitors

- Color Matching/Formulating Systems

- Sensors, Thermocouples

- Design of Experiments (DOE) Software

- Motion or Position Controls

- Screw Design/Analysis Software

- Level Sensors & Controls

- Recycled/Reprocessed Materials -Pelletized

- Closed-loop Process Control Systems

- Machine Monitoring/Alarm Systems

- Environmental Monitoring & Analysis

- Biodegradable, Photodegradable Resins & Compounds

- Pressure Sensors, Transducers

- Laser Cutting Systems