Thermoforming

In thermoforming, plastic sheet is heated to a pliable temperature then shaped into a part by a male and female mold with the help of a vacuum. Categorized as thin-gauge or thick-gauge, the process is used to create products like clamshells, trays, and cups.

ESSENTIAL READING

VIEW ALL‘Back to Basics’ Fuels More Innovation at Thin-Gauge Former

Shift from private to capital ownership give Tray-Pak a boost.

Read MoreThermoforming PLA: How to Do It Right

Polylactic acid (PLA) resins are made from 100% renewable resources such as corn, sugar beets, or sugarcane.

Read MoreHow to Thermoform Top-Quality IMD Inserts

Wider adoption of in-mold decorating (IMD) for demanding industries like automotive, appliances, and consumer electronics will require thermoformers to have the right know-how and equipment.

Read MoreLatest Thermoforming News And Updates

Origin Materials Unveils CapFormer for Producing PET Caps

Factory acceptance test completed at commercial scale.

Read MoreInteractive Training for Injection, Extrusion and Other Processes

Paulson has four in-booth stations demonstrating its various training solutions.

Read MoreHigh-Throughput, Robust Thermoformer

NPE2024: WM Thermoforming’s new generation of FC1000 IM2 offers the highest throughput per square feet.

Read MoreUpgraded Former is Faster, More Precise

New features reportedly offer more efficient production of trays, containers, hinged boxes, pallets, blisters, lids and technical products.

Read MoreWinners Announced for SPE Thermoforming 2023 Parts Competition

More than 30 entries were considered, including 10 in the Sustainability category.

Read MoreHagan Named SPE Thermoformer of the Year

Fifty year veteran of thermoforming industry to receive award during October’s conference.

Read MoreFeatured Posts

A Processor's Perspective: What's Driving Growth in Heavy-Gauge Thermoforming

Key factors for the progress are innovative materials, advanced automation and precision engineering.

Read MoreThermoformed Container Keeps Battery Cells Safe

Despite last-minute design changes and other unexpected roadblocks, thermoformer TriEnda works with a key supplier on innovative reusable shipping container.

Read MoreKiefel Showcasing New Equipment and Sustainable Solutions

NPE2024: Kiefel is demonstrating its Speedformer KMD 90.1 Premium machine and cutting-edge technology for efficient polymer cups and fiber sip-lid production.

Read MoreUS Merchants Makes its Mark in Injection Molding

In less than a decade in injection molding, US Merchants has acquired hundreds of machines spread across facilities in California, Texas, Virginia and Arizona, with even more growth coming.

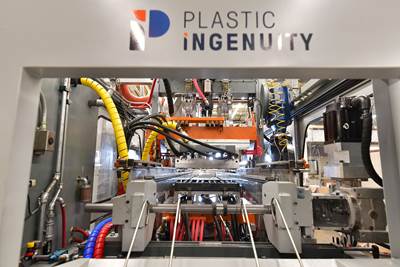

Read MoreIngenuity Is Part of This Former’s Name, and in Its DNA

Plastic Ingenuity started in a garage in 1972 and through a commitment to developing best-in-class products stands today as one of the largest custom thermoformers in the world.

Read MoreCobot Creates 'Cell Manufacturing Dream' for Thermoformer

Kal Plastics deploys Universal Robot trimming cobot for a fraction of the cost and lead time of a CNC machine, cuts trimming time nearly in half and reduces late shipments to under 1% — all while improving employee safety and growth opportunities.

WatchFAQ: Thermoforming

How to fix a thermoformer?

Some shot-to-shot misalignment may occur even if the above adjustments to the rail are made. When issues arise, especially today, when OEMs’ technicians can’t travel to service and maintain equipment in person, it can be helpful to have a checklist for troubleshooting.

Here are 10 of the most important steps for troubleshooting misalignment and other common issues in thermoforming.