Heating and Cooling

Temperature control in plastics processing includes mold temperature control, chillers, cooling towers, and heat exchangers.

ESSENTIAL READING

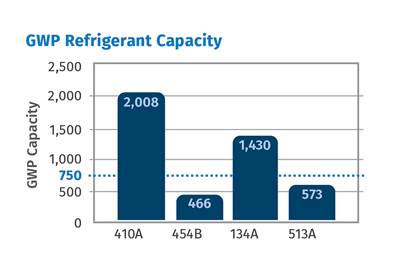

VIEW ALLTemperature Control: What You Need to Know to Comply With New Cooling-Fluid Regs

Beginning the first of this year, 12 states are following EPA bans on potentially damaging cooling fluids. Chiller suppliers have adjusted equipment designs to accommodate the new regulations. Here’s what all this means to processors.

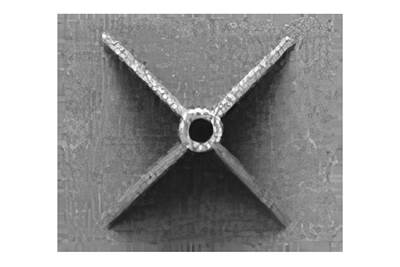

Read MoreHow to Reduce Sinks in Injection Molding

Modifications to the common core pin can be a simple solution, but don’t expect all resins to behave the same. Gas assist is also worth a try.

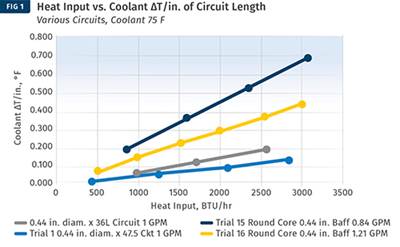

Read MoreImprove The Cooling Performance Of Your Molds

Need to figure out your mold-cooling energy requirements for the various polymers you run? What about sizing cooling circuits so they provide adequate cooling capacity? Learn the tricks of the trade here.

Read MoreCooling the Feed Throat and Screw: How Much Water Do You Need?

It’s one of the biggest quandaries in extrusion, as there is little or nothing published to give operators some guidance. So let’s try to shed some light on this trial-and-error process.

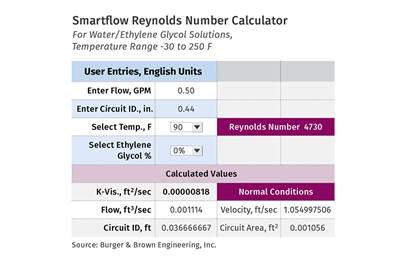

Read MoreCooling Geometry and the Reynolds Calculation

The original Turbulent Flow Rate Calculator worked well with a round circuit diameter, such as a drilled passage, but not as well using hydraulic diameters. Here’s how the problem was fixed.

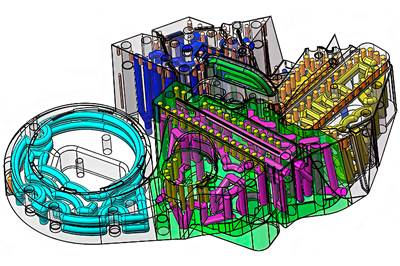

Read MoreHow to Know the True Value of Conformally Cooled Injection Molds

What’s the return on investing in a new mold with conformal cooling to boost productivity? Will it pay for itself? How soon? Here’s a case study on how to answer those questions.

Read MoreLatest Heating & Cooling News And Updates

Industry Vet Duff Joins ACS Group

With 37 years of experience on both machinery and processor side, Michael Duff to handle aftermarket 大象传媒 for auxiliary equipment manufacturer.

Read MoreConair Names New Head of Customer Care

Jared Helfrich to direct the efforts of the machine builder’s growing customer care group, combining its existing parts and service and repair organization with a new range of fast-growing customer services.

Read MoreACS Group Adds Regional Sales Manager

Richard Gutierrez named Southwest regional sales manager.

Read MoreTemperature Control Unit (TCU) Modulates Heat Output in Real Time

Delta T Systems’ Smart series water TCU features “Vari-Heat” technology for greater precision and efficiency.

Read MoreCooling Bore Creates Turbulent Flow

Hasco says its Cooling Tornado facilitates turbulent flow, boosting cooling effectiveness by up to 20%.

Read MoreGlobeius Acquires Plastixs

The Miami-based firm representing an array of plastics processing-related technologies has acquired the Massachusetts-headquartered supplier of manifolds, hoses, leak monitors, flow meters and more.

Read MoreFeatured Posts

Temperature Control: What You Need to Know to Comply With New Cooling-Fluid Regs

Beginning the first of this year, 12 states are following EPA bans on potentially damaging cooling fluids. Chiller suppliers have adjusted equipment designs to accommodate the new regulations. Here’s what all this means to processors.

Read MoreIs Your Water System Setup Helping or Hurting Your Molding Plant Productivity?

The plant water system is a critical component of an injection molding facility. A poorly designed or maintained water-cooling system can have a serious impact on production efficiency and cause many maintenance issues. Here’s what you need to know — and ask — to prevent those problems.

Read MoreCaptive Molder Beefs Up Auxiliaries to Boost Quality, Consistency

SeeScan adds conveying, drying, feeding and chilling technologies to improve quality — and enhance employee safety — in production of its underground/underwater inspection systems.

WatchFollow These Best Practices When Working With Heat Transfer Fluids

Effectively choosing, operating and maintaining thermal fluid can positively impact productivity in plastics processing.

Read MoreSystem Offers 'Lights Out' Mold-Channel Cleaning & Diagnostics

New system automatically cleans mold-cooling lines—including conformal channels—removing rust and calcium, among other deposits, while simultaneously testing for leaks, measuring flow rate and applying rust inhibitor.

WatchHow to Reduce Sinks in Injection Molding

Modifications to the common core pin can be a simple solution, but don’t expect all resins to behave the same. Gas assist is also worth a try.

Read MoreFAQ: Heating & Cooling

Are Conformally Cooled Injection Molds Worth It?

When evaluating cost-reduction projects in injection molding, the discussion typically centers around cycle-time reduction and the cost to implement the change. This article explores the true value of conformally cooled injection mold in a very specific case. That case is when the molder can sell more product than it can make on a 24/7 basis.

How to Fix Mold Temperature Control?

Mold-temperature control is just one of many process elements that can affect the quality of an injection molded part. In a perfect world, anyone running a particular mold would know what the mold designer set as the ideal temperature and flow rate for the cooling water. In reality, operators and setup personnel don’t always know these settings and/or something changes so that it is necessary to re-establish them by trial and error.

How to Improve The Cooling Performance Of Molds?

The first law of thermodynamics states that energy cannot be created or destroyed, but only transferred from one place to another. If you think of an injection mold as a closed thermodynamic system, you can account for the energy entering and leaving the system. A shot of molten plastic injected into a mold is the energy input, and energy leaves by various mechanisms. Some of the energy (heat) is carried away in the ejected parts and some is removed by the cooling system. It is less obvious, but some energy will also go into the surrounding environment when a mold is heated substantially above room temperature.

Heating & Cooling Supplier Categories

- Drive Controls

- Recording Instruments

- Cooling-Water Treatment Chemicals

- Heat-Distortion Modifiers

- Dewpoint Monitors/Moisture Analyzers

- Flow Monitoring/Control Devices (for Liquids)

- Flow Monitoring/Control Devices (for Liquids)

- Pressure Controllers, Monitors

- Controllers, Monitors

- Sensors, Thermocouples

- Motion or Position Controls

- Conductive Additives

- Heat Stabilizers for PVC

- Level Sensors & Controls

- Closed-loop Process Control Systems

- Machine Monitoring/Alarm Systems

- Pressure Sensors, Transducers