Plastics Industry Automation

Automation in the Plastics Industry involves robots, cobots, molding cells, part pickers, and end-of-arm-tooling.

ESSENTIAL READING

VIEW ALLWhat to Look for in High-Speed Automation for Pipette Production

Automation is a must-have for molders of pipettes. Make sure your supplier provides assurances of throughput and output, manpower utilization, floor space consumption and payback period.

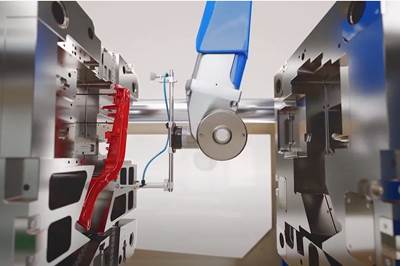

Read MoreHow to Automate High-Precision ‘Micro’ Insert Molding

What does it take to automate a horizontal injection molding cell to handle micro-sized inserts and molded parts? General-purpose top-entry robots and tooling may not be up to the job.

Read MoreHow to Plan and Implement Automation in an Injection Molding Plant

There is no “one size fits all” solution in automation. When considering what it would look like in your plant, hone in on the staff, products, space, and goals that are specific to you and the automation system that you will be installing.

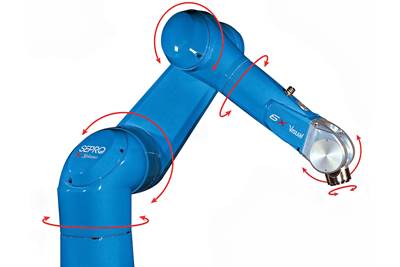

Read MoreAUTOMATION—PART 2 When to Consider Six-Axis Articulated-Arm Robots

Extraordinary versatility suits articulated-arm robots to a wide variety of operations, from loading inserts and unloading parts to decorating, assembly and testing. They also pair well with Cartesian robots. Many mounting options and improved speed and ease of programming add to their flexibility.

Read MoreHow to Make Your Pneumatics ‘Smart’

Emerson’s Avantics Smart Pneumatics Analyzer digitizes the analog pneumatic environment and monitors and analyzes key operating data.

Read MoreImplementing Automation Systems: How to Do It Right

If you’re thinking of putting a complex automation system for high-volume consumables into your plant, consider these tips on making sure both you and your supplier are ready to give it the best chance of success.

Read MoreLatest Automation News And Updates

Cobot Line Increases Top Speed

Universal Robots says for pick-and-place applications, the new UR15 delivers up to 30% cycle time improvements compared to prior UR models.

Read MoreNorth American Robot Orders Flat in First Quarter

The Association for Advancing Automation (A3) reported a 15% rise in order value, however, and announced plans to track cobot sales.

Read MoreEngel Opens Injection Molding Machine Manufacturing Plant in Mexico

With a capacity to produce between 180 and 200 injection molding machines per year, Engel has inaugurated its first production plant on the North American continent. This long-term project will expand in phases to offer vertical integration in manufacturing, automation and a solutions center.

Read MoreAI-Powered Drying Technology

Conair’s ResinWorks multihopper drying system automatically maintains process-ready resins at perfect temperatures, prevents overdrying and delivers big energy savings.

Read MoreMake Better Automation Selection Choices

Three leading custom injection molders will share their firsthand experiences with the how’s, when’s, what’s and why’s of different injection molding automation projects in this PTXPO Discovery Workshop.

Read MoreNorwalt Automation Expands Tampa Footprint, Capacity

The new 28,000-square-foot site in Tampa, Florida, will focus on machine and system integration activities for various sectors.

Read MoreFeatured Posts

Paperless ‘Smart Factory’ Based on Automated Production Monitoring

Tier 1 automotive molder’s home-built production-monitoring and ERP systems, designed for “the little guy,” boost its efficiency rating and profits.

Read MorePTXPO Recap: Smarter Resin Drying & Conveying Automation

Check out what you missed on the PTXPO show floor. In this video, Editorial Director Jim Callari breaks down how AI is changing the game in plastics manufacturing.

WatchHow This Custom Compounder Leverages AI to Drive Innovation, Sustainability

Alterra has stepped up its cutting-edge Industry 4.0 technology with its own AI platform to further increase its efficiencies.

Read MoreGolf Equipment Manufacturer Scores Higher Productivity With Automated Cell

Ping was able to reduce labor and waste at its production facility in Phoenix via an automated molding cell courtesy of Wittmann.

Read MoreSmooth Operators: Vibration Compensation Improves Robot Performance

Ulendo is working to apply its vibration compensation algorithm to robots. This application is more complex than its initial market of fused filament fabrication 3D printers, but could result in faster, cheaper robots.

Read MorePTXPO On Display: LS Mtron’s Smart Solution

Get a preview of technology you’ll see live on the Plastics Technology Expo show floor March 18-20 in Rosemont, Illinois.

WatchFAQ: Automation

How to add automation to injection molding?

There is no “one size fits all” solution in automation. When considering what it would look like in your plant, hone in on the staff, products, space, and goals that are specific to you and the automation system that you will be installing.