Tooling for Plastics Production

Tooling for plastics production includes molds, mold components, ejector pins, mold bases, nozzles, mold cores, mold cavities, conformal cooling.

Narrow Your Tooling Search

ESSENTIAL READING

VIEW ALLAIM Institute Continues to Grow Plastics Education and Training on 10th Anniversary

The AIM institute was created in response to the rising need for skilled injection molding professionals, providing individuals with a fundamental understanding of plastic rheology and plastic flow through a mold.

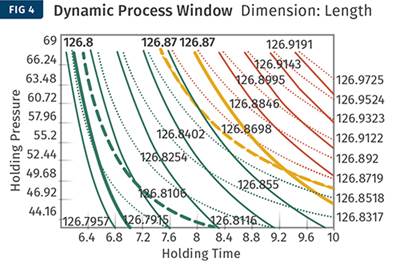

Read MoreOptimizing Pack & Hold Times for Hot-Runner & Valve-Gated Molds

Using scientific procedures will help you put an end to all that time-consuming trial and error. Part 1 of 2.

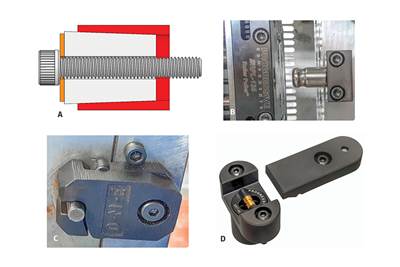

Read MoreWhat You Need to Know About Leader Pins and Bushings

There’s a lot more to these humble but essential mold components than you might suspect. Following the author’s tips could save much time, money and frustration.

Read MoreThree Key Decisions for an Optimal Ejection System

When determining the best ejection option for a tool, molders must consider the ejector’s surface area, location and style.

Read MoreBest of Fattori, Tooling Know How

In this collection of articles Jim Fattori offers his insights on a variety of molding-related topics that are bound to make your days on the production floor go a little bit better.

Read MoreHow To Design Three-Plate Molds – Part 4

There are many things to consider, and paying attention to the details can help avoid machine downtime and higher maintenance costs — and keep the customer happy.

Read MoreLatest Tooling News And Updates

Expanded Air Poppet Valve Series Supports Molded Part Ejection

CUMSA expands Air Poppet Valve series with a smaller size dimension and a first-time size offering in inches.

Read MoreSoftware Suite Creates Integrated Workflows for Optimizing Moldmaking

Eastec 2025: The HxGN Mould and Die Suite includes VISI, WORNC, NCSIMUL and datanomix tools to provide an integrated workflow from design/engineering to manufacturing and automation.

Read MoreCooling System Saves Energy Directly In The Mold

Hasco’s Cooling Tornado offers simplified installation and quick retrofits, and also enables customized shortening, further supporting uncomplicated installation on existing systems.

Read More