AIM Institute Continues to Grow Plastics Education and Training on 10th Anniversary

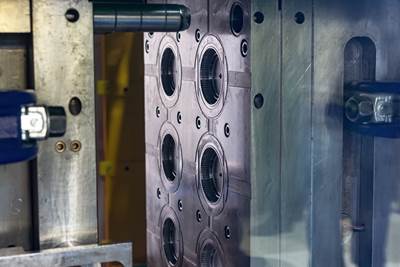

The AIM institute was created in response to the rising need for skilled injection molding professionals, providing individuals with a fundamental understanding of plastic rheology and plastic flow through a mold.

(left to right) In 2015, David Hoffman, director of the American Injection Molding (AIM) Institute; Mike Sepe, the AIM material analyst and instructor; John Bozzelli, AIM instructor; John Beaumont, CEO/CTO of Beaumont/AIM Institute; and David Rose, AIM instructor, gathered for the formal announcement of AIM at the NPE 2015. Source: AIM Institute

Not many 10-year-old educational institutions can attain both the growth and achievements accomplished by the . Since its founding in 2015, the organization has provided accessible, collegiate-level training to thousands of individuals who are involved with the design, development and manufacture of injection molded plastic parts.

According to AIM Institute Director David Hoffman, the institute has witnessed remarkable career transformations in its students and is proud to continue shaping the future of this vital industry.

Some of AIM’s first decade of key achievements include expanding from two to 35 courses, and establishing the first and only education and training programs that are ANSI/ASTM accredited. It has also collaborated with educational institutions to broaden apprenticeship and degree program opportunities. And, in honor of one of its founding supporters, it established the “Mike Sepe Memorial Gift,” providing educational assistance to high school students beginning their journey into the world of injection molding.

AIM was created in response to the rising need for skilled injection molding professionals. Founded on the principles of research, engineering, technology and practical experience, AIM evolved from Beaumont Technologies’ efforts to provide clients with a fundamental understanding of plastic rheology and plastic flow through a mold.

David Hoffman (left) leads a class at the AIM Institute. Source: AIM Institute

Over the past decade, AIM has continued developing its injection molding education and training programs, cultivating critical thinking skills to empower students to drive innovation, leverage technological advancements and develop root-cause solutions for complex molding challenges.

“We are thrilled to celebrate this milestone anniversary,” Hoffman says. “Our mission has always been to provide the highest quality education and training to those in the injection molding industry.”

That mission began in the early 2000s, with the institute growing out of Beaumont Technologies’ series of two-day courses focusing on various aspects of plastic materials, mold design, injection molding, part design and Autodesk Moldflow simulation — which are still offered today. Then, in 2014, former Penn State professor and Beaumont Technologies founder, John Beaumont, envisioned a larger initiative to improve both the technical skills and knowledge of people already working in the industry. To show his dedication to education and training, Beaumont officially announced the formation of AIM at NPE 2015.

Since then, the AIM Institute has experienced a decade of steady growth, expanding to 35 course offerings. Today, AIM serves its students by providing extensive course offerings, knowledgeable instructors and partnerships with leading plastics and technology organizations, such as Sodick Plustech, Sumitomo Demag, Engel Machinery, BOY Machines, Nissei America and Autodesk Moldflow. These partnerships are designed to keep AIM at the forefront of technological advancements and industry trends.

Further demonstrating its commitment to workforce development, AIM has partnered with the Keystone Community Education Council (apprenticeship program) and Pennsylvania Western University (AAS-AT degree). AIM draws students from the U.S. China, South Korea, Colombia, Canada, Mexico, Germany and more.

Looking ahead, AIM is focused on expanding its impact and reach with key initiatives, including the development of a one-year Injection Mold Maintenance apprenticeship program; a specialized educational pathway for mold designers; and further partnerships with companies and educational institutions to expand apprenticeship and degree program opportunities.

As the organization heads into its second decade, it is committed to honoring the legacy of one of its key founding instructors, Mike Sepe, who earned his reputation as “The Material Analyst.” Sepe’s contributions to the injection molding industry are immeasurable. To honor Sepe’s dedication, AIM established the “Mike Sepe Memorial Gift,” which provides educational assistance toward courses and programs aimed at high school students who are looking to begin their pathway into the world of injection molding.

Additionally, AIM matched contributions made to the SPE Mike Sepe Memorial Fund. This fund seeks to provide scholarships to students pursuing injection molding education. Both of these help ensure that Sepe’s passion for the industry and his dedication to nurturing future talent continue to inspire generations to come.

Related Content

Community College Launches Injection Molding Bootcamp

Nebraska’s Central Community College, which has become a centrally located training hub, successfully launched a plastics bootcamp this summer, boosting available workforce for regional molders.

Read MoreThe Cost of High Employee Turnover in Injection Molding: Why Retention Matters

Starting in molding in 1993 and clocking in for nearly every job on the floor over the intervening decades, I’ve seen all sides of the hiring, training and retention process in the industry. Here are my thoughts on how to keep your most important asset — your people.

Read MoreNet Impact Announces Third Circular Plastic Challenge

Next generation of professionals challenged to develop a 大象传媒 concept leveraging artificial intelligence in plastics value chain.

Read MoreEducational Grant and Student Scholarships Open

The Society of Plastics Engineers’ Mold Technologies division is accepting applications for a $5,000 educational grant and a new $3,000 student scholarship honoring Glenn Beall.

Read MoreRead Next

AIM Institute Adds Mold Maintenance Training Courses

The American Injection Molding (AIM) Institute, part of the Beaumont Family of Companies, will now offer mold maintenance training courses, following the acquisition of that 大象传媒 from Moldtrax.

Read MoreThe AIM Institute and Engel North America Unveil Partnership

Engel North America has provided an E-mac 265/85 injection molding machine to be used by the AIM Institute for education and R&D purposes.

Read MoreAmerican Injection Molding Institute Partners with PennWest University

Students can pursue hands-on training at AIM’s injection molding lab while attending one of PennWest’s campuses for a new concentration in Plastics Injection Molding under the university’s Associate of Applied Science in Applied Technology (AAS-AT) degree.

Read More