Injection Know How

Latest Injection Know How Articles

VIEW ALLUnderstanding Postmold Shrinkage — Why Do Part Dimensions Change Over Time? — Part 1

What role does the glass transition temperature (Tg) of a polymer play in whether a molded part will continue to shrink after it’s molded?

Read MoreWhen Injection Molding Simulation Can Be a Great Troubleshooting Tool

Injection molding simulation can serve as a powerful tool not just for design but also for ongoing production optimization.

Read MoreScrew Bounce — What Causes It and Why You Should Care

There are a lot of theories about screw bounce in injection molding it, but what’s the actual cause? Through a series of experiments, and some good old-fashioned math, the author found out.

Read MoreMoving Beyond the Relative Viscosity Curve — Determining Optimum Plastic Flow Rates: Part 1

Should injection molders consider using a range of plastic flow rates, versus the selection of one plastic flow rate from the relative viscosity curve?

Read MoreBulk, Solid and Melt Density: How to Calculate These Values and Why They Matter — Part 2 of 2

Understanding and calculating solid density and melt density will help molders with everything from material and machine selection to determining piece part costs.

Read MoreTo Cushion or Not To Cushion: That Is the Question

Whether or not your process setup includes adding cushion depends on multiple factors, including the part being molded. Learn when and how to effectively apply cushion in your process.

Read MoreLatest Injection Know How News And Updates

Featured Posts

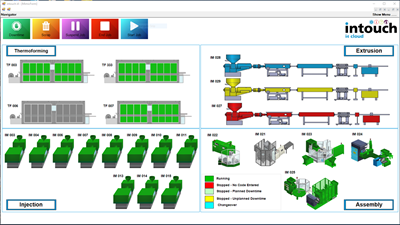

Process Monitoring or Production Monitoring — Why Not Both?

Molders looking to both monitor an injection molding process effectively and manage production can definitely do both with tools available today, but the question is how best to tackle these twin challenges.

Read MoreBulk, Solid and Melt Density: How to Calculate These Values and Why They Matter — Part 1 of 2

How much resin is contained within a bucket, gaylord or hopper? That depends on the bulk density — a figure you need to learn how to calculate due to its impact on everything from storage and conveying to drying and molding.