Pipe, Profile and Tubing Extrusion

Latest Pipe, Profile & Tubing Extrusion Articles

VIEW ALLRollepaal Launches Standardized Lines for Oriented PVC Pipe

System requires no specialty additives or complex line configurations to achieve orientation.

Read MoreTire-Driven Gantry for Heavy-Duty Applications

Designed for the smooth, even take-up of products ranging from fiber-optic cables to electrical power cables.

Read MoreA Processor's Guide to Making World-Class Multilumen Tubing

Process innovation is pushing catheter design to the limit. Here are Lubrizol’s tricks of the trade.

Read MoreServo-Controlled Coiler for Tubing, Flexible Profiles

The technology is said to ensure maximum accuracy and repeatability for high-quality product winding.

Read MoreThis Tubing Processor Is Used to the 'Hard Stuff'

Kent Elastomer Products has emerged from its beginnings as a supplier of latex dip tubing to a leading manufacturer of high-end tight tolerance tubes for a range of applications.

Read MoreKM to Produce Pipe, Profile, Sheet Extruders in US

KraussMaffei to make extruders in Kentucky to reduce lead times and enhance customer support.

Read MoreLatest Pipe, Profile & Tubing Extrusion News And Updates

Automatic Tube and Hose Coilers Minimize Operator Involvement

Units offer higher speeds and efficiencies for downstream operations in flexible pipe.

Read More‘Revolutionary’ Extrudable PPS for Sustainable Piping

Syensqo’s Ryton PPS XE-5000NA boasts exceptional chemical and permeation resistance.

Read MoreFormer PLASTICS CEO Radoszewski Joins Pipe Maker

Plastics and pipe industry veteran joins Lane in newly created role.

Read MoreMachine Builders, Compounder, Processor Combine on Balloon Forming Technology

US Extruders partners with Colin Sutherland, Poba Medical and Compounding Solutions on turnkey balloon tubing extrusion and balloon forming technology.

Read MoreReel Power Buys Novatec's Downstream Extrusion Line

Move enables Novatec to focus on core 大象传媒es while giving Reel Power the ability to furnish turnkey systems.

Read MoreCorrugated Tube Crossheads

Multiport spiral-flow design is said to provide a balanced compound distribution with no weld lines to the corrugator.

Read MoreFeatured Posts

Extrusion Excellence: This Year's Top Stories

Revisit the year’s most popular articles on extrusion technology and processes, showcasing innovations, best practices, and the trends that captured the plastics processing community’s attention.

Read MoreMaking Gains in the Drain Game

AWD blends extrusion and thermoforming technologies with plenty of home-brewed equipment and processes to keep water away from where it isn’t supposed to be.

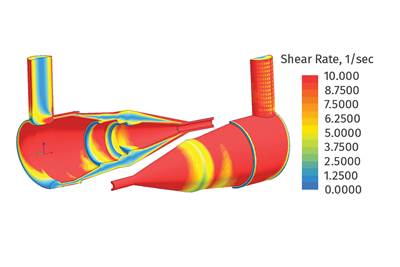

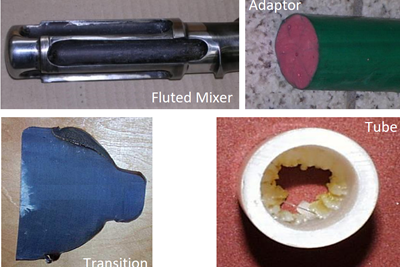

Read MorePart 2 Medical Tubing: Use Simulation to Troubleshoot, Optimize Processing & Dies

Simulation can determine whether a die has regions of low shear rate and shear stress on the metal surface where the polymer would ultimately degrade, and can help processors design dies better suited for their projects.

Read MoreHow to Decrease the Extrudate Temperature in Single-Screw Extruders

In many cases, decreasing the discharge temperature will improve product quality and perhaps even boost rate. Here are ways to do it.

Read MoreMedical Tubing: Use Simulation to Troubleshoot, Optimize Processing & Dies

Extrusion simulations can be useful in anticipating issues and running “what-if” scenarios to size extruders and design dies for extrusion projects. It should be used at early stages of any project to avoid trial and error and remaking tooling.

Read MoreTight-Tolerance Molder Dips Toe in Extrusion Waters

Midwest Precision Molding brings extrusion capacity in-house to assist a customer that was having a sourcing issue with its existing overseas suppliers.

Read More