Extrusion Know How

Latest Extrusion Know How Articles

VIEW ALLHow Compression Ratio Impacts Extruder Performance

Let’s investigate how compression ratio affects performance of an extruder processing LLDPE.

Read MoreUse a Process Assessment to Determine the Benefits of Screw-Design Modification

This type of analysis analysis will provide the converter with a clear picture of whether changes to the screw could provide economic gains through increased rate, yield, and quality.

Read MoreHow To Identify Resin Degradation in Single-Screw Extruders

Degradation can occur in many single-screw extrusion operations, and typically occurs due to minor design flaws in the screw. Here is how to track it down.

Read MoreOptimizing Melt-Fed Single-Screw Extruders on Compounding Lines

The main problem with melt-fed extruders that are starve-fed is setting the depth of the metering channel. In this scenario, we describe how this problem was solved.

Read MoreWhat You Need to Know About Roll-Cooling Design

Cooling rolls might not look like high-tech machines, but the fact is there is a surprising amount of technology involved in their design, manufacture and use. Here’s what you need to know.

Read MoreWhat You Need to Know About Melt-Temperature Measurement in Single-Screw Extruders

Measuring the discharge temperature is not so simple, especially when using thermocouples positioned in the transfer line just upstream of the die.

Read MoreLatest Extrusion Know How News And Updates

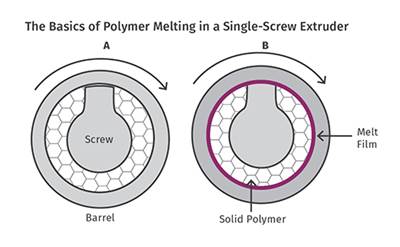

EXTRUSION: Melting 101

Learn the basics on how polymer melts in a single screw. Barrel temperature plays less of a role than you might think.

Read MoreFeatured Posts

How to Select the Right Cooling Stack for Sheet

First, remember there is no universal cooling-roll stack. And be sure to take into account the specific heat of the polymer you are processing.

Read MoreWhat's Restricting My Output Rate?

In a single-screw extruder, it could be an improperly designed barrier flighted entry section. Here’s why.

Read MoreHow to Decrease the Extrudate Temperature in Single-Screw Extruders

In many cases, decreasing the discharge temperature will improve product quality and perhaps even boost rate. Here are ways to do it.

Read MoreWhy Are There No 'Universal' Screws for All Polymers?

There’s a simple answer: Because all plastics are not the same.

Read MoreIn Single Screw Extruders, Mixing Starts in the Melting Process

While the melting process does not provide perfect mixing, this study shows that mixing is indeed initiated during melting.

Read More