Engineering Resins

Engineering resins are a category of polymers typically used in more demanding applications than commodity resins. They typically have properties that offer higher performance such heat, chemical, and impact strength resistance which makes them well suited to replacement of metals and other materials in a wide range of electrical/electronic, automotive, aerospace, medical, and industrial applications. They include volume engineering resins ABS, PC, and nylons 6 and 66, as well as PBT, PEEK, PPO, PPS, higher-temperature nylons such as PPAs (polyphthalamides), POM, and LCPs.

ESSENTIAL READING

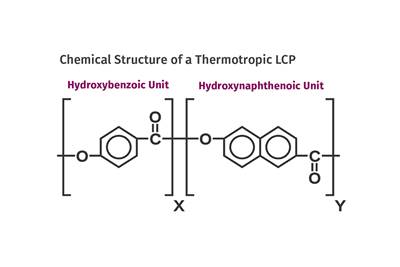

VIEW ALLTracing the History of Polymeric Materials, Part 28: Making LCP's Melt Processable

Liquid-crystal polymers based on a single monomer produces a polymer with a very high melting point.This presents two problems. Here’s how they were solved.

Read MoreTracing the History of Polymeric Materials, Part 27: Liquid-Crystal Polymers

Liquid-crystal polymers debuted in the mid-1980s, but the history of the chemistry associated with this class of materials actually starts a century earlier.

Read MoreTracing the History of Polymeric Materials, Part 26: High-Performance Thermoplastics

The majority of the polymers that today we rely on for outstanding performance — such as polysulfone, polyethersulfone, polyphenylsulfone and PPS — were introduced in the period between 1965 and 1985. Here’s how they entered your toolbox of engineering of materials.

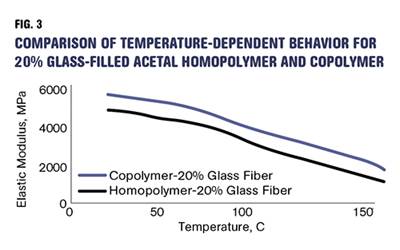

Read MoreHow Do You Like Your Acetal: Homopolymer or Copolymer?

Acetal materials have been a commercial option for more than 50 years.

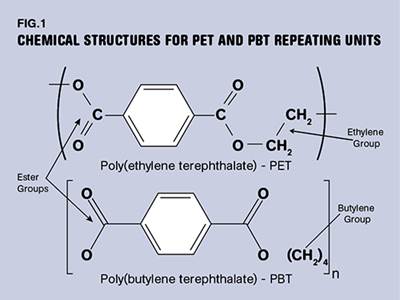

Read MorePBT and PET Polyester: The Difference Crystallinity Makes

To properly understand the differences in performance between PET and PBT we need to compare apples to apples—the semi-crystalline forms of each polymer.

Read MoreTracing the History of Polymeric Materials: Polyphenylene Oxide Blends

PPO was a promising new high-performance thermoplastic, but it could be made useful only by mixing it with a humble commodity resin.

Read MoreLatest Engineering Resins News And Updates

SABIC Introduces New Grade Extem RH Resin

Extem RH1017UCL will support data communication infrastructure applications.

Read MoreBASF Ultrason D High Flow PESU Blend for Injection Molding

Blend targeted at molding applications in data and energy transmission, smart electronics and e-mobility

Read MoreXenia Whitened Shade Materials

Product will enable greater coloring options in carbon-reinforced thermoplastic compounds.

Read MoreSABIC Conductive Noryl GTX LMX310 Resins for Dimensional Stability

Polypropylene ether blend for automotive exteriors resist heat and moisture.

Read MoreAmerichem EcoLube MD PFAS Free Internally Lubricated Compounds for Health Care Applications

Americhem has formulated EcoLube compounds in a wide variety of base resins.

Read MoreStar Plastics PFAS-Free Compounds

New polycarbonate compounds free from per and poly flouoralkyl substances.

Read MoreFeatured Posts

Injection Molding Stock-Shape Parts in High-Temperature Materials

Patented technology is described as a hybrid that uses a specialized tool, a standard injection molding machine and off-the-shelf components to replace compression molding and extrusion for large stock shapes.

Read MorePolymer Showdown — PPO vs. PA66: May the Best Material Win

Second in a series, an expert from plastics engineering consultancy The Madison Group pits leading thermoplastics against each other to see how they differ in processing characteristics, chemical resistance, thermal and mechanical performance, and more.

Read MorePolymer Showdown — PC/ABS vs. PC/PBT — May the Best Material Win

First in a series, experts from plastics engineering consultancy The Madison Group will pit leading thermoplastics against each other to see how they differ in processing characteristics, chemical resistance, thermal and mechanical performance, and more.

Read MoreAutomotive Awards Highlight Emerging Technologies

Annual SPE Automotive event gives nods to several ‘firsts’ as well as sustainability.

Read MoreNPE2024 Materials: Spotlight on Sustainability with Performance

Across the show, sustainability ruled in new materials technology, from polyolefins and engineering resins to biobased materials.

Read MoreTeknor Apex Presents Daily Hourly Sessions on Broad Range of Materials for Sustainability and Electrification

NPE 2024: Teknor Apex discusses its recyclable thermoplastic elastomers and much more between Tuesday and Thursday

Read MoreFAQ: Engineering Resins

Lower mold temperatures and the associated faster cooling rates produce higher levels of internal stress in the molded part. This arises in part because of the more rapid development of the frozen layer as the material flows into the mold. This can result in flow lines that are visual evidence of impeded flow. It also produces a higher degree of retained orientation in the more rapidly cooled layers at the exterior surface.