Liquid Injection Molding (LIM) and Liquid Silicon Rubber (LSR) Injection Molding

Latest LIM & LSR Molding Articles

VIEW ALLLSR Cold Runner Deploys Servo-Actuated Needles for Smart Operation

Elmet says the patent-pending SMARTshot I cold runner measurement and control concept uses servo-actuated nozzle needles to enable automatic startup without additional sensors.

Read MoreSumitomo (SHI) Demag North America Names New Executive Leadership

The company has appointed Liam Burns to serve as president and John F. Martich III to serve in the expanded role of chief operating officer.

Read MoreLSR Molding Dosing System Designed for Precision, Efficiency and Compliance

The system offers a variety of features to successfully produce high-quality silicone parts with the most economic use of material, space, working time and energy.

Read MorePTXPO Preview: Nissei Showcases LSR Molding

In cooperation with Elmet, Nissei will mold a nasal respiratory valve from LSR utilizing a valve-gated cold runner.

Read MorePTXPO Preview: Wittmann Showcases LSR Molding, Central Conveying Demonstration

A 121-ton SmartPower injection molding machine equipped for LSR processing will join a demonstration of Wittmann’s Codemax RFID-coded manifold, among other technologies.

Read MoreServo-Hydraulic Injection Molding Machine With an Electric Injection Unit Premieres

Fakuma 2024: Wittmann Battenfeld says the 2K SmartPower Combimould features a new electric injection unit option.

Read MoreLatest LIM & LSR Molding News And Updates

Completely Connected Molding

NPE2024: Medical, inmold labeling, core-back molding and Industry 4.0 technologies on display at Shibaura’s booth.

Read MoreSlimmer All-Electric Press Debuts

NPE2024: A slimmed-down version of Engel’s all-electric, e-mac injection molding machine is among eight displays, which also include LSR micromolding, quick mold changes and a cube mold.

Read MoreAll-Electric IMM Advances for Packaging, Medical and LSR

NPE2024: Sumitomo SHI Demag’s show focus is on the application of all-electric injection molding machine technology for a variety of markets and components.

Read MoreIMM Cells Display Communications, Energy Measurement and Energy Recovery

NPE2024: Wittmann is featuring five injection molding machines incorporating its range of robotics and auxiliaries, with all products employing industry 4.0 communications, energy measurement and a brand-new red color.

Read MoreUpdated Control, Cooling Water Distribution, Electromechanical Ejector and Injection

NPE2024: Boy’s U.S. subsidiary marks its 50th anniversary in Orlando with six machines and U.S. intros for the Procan ALPHA 6 control, and hybrid ejectors and injection units.

Read MoreMidtonnage Hybrid Range With Compact Footprint Launches

NPE2024: Milacron has the global launch of its new M-Series injection molding machine line featuring a large clamp stroke as standard in a line of midtonnage, compact-footprint machines.

Read MoreFeatured Posts

Milacron’s Massive Booth Highlights Multiple Brands

NPE2024: Coinjection of postconsumer resin, in-mold decoration, LSR micromolding and bioplastics processing are just some of the machine displays at Milacron's booth.

Read MoreInjection Machines Use Novel Two-Stage Molding System

EdeX servohydraulic presses from Taiwan are the first to employ the Inject-EX plasticating system from Md Plastics.

Read MoreFinding a Niche in LSR Tooling

20 years ago, southern California moldmaker M.R. Mold & Engineering pivoted to LSR tooling, giving it a foothold in a challenging but growing market.

Read MoreCustom Molder Manages Growth on Several Fronts

Adding people, plants and machines, expanding capabilities in LSR, high-tonnage presses, automation and 3D printing—EVCO Plastics maintains momentum through challenging times.

Read MoreHow a Molder Embraces Change While Sticking to Its Roots

For MDS Manufacturing, its first decade in ´óĎó´«Ă˝ has been one of nearly constant change. But the two brothers who started it have never strayed from the company’s roots and the lessons about the molding ´óĎó´«Ă˝ they learned from their father.

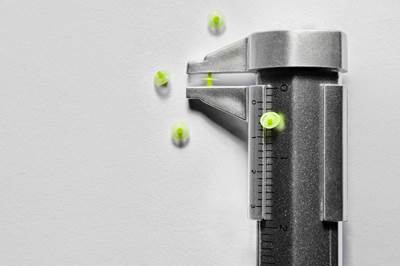

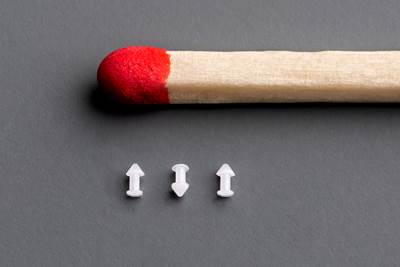

WatchMicro-Injection Molding LSR: Exploring the Limits of What’s Possible

Molding delicate LSR parts weighing 0.5 mg in 32 cavities requires high precision and repeatability in molding and careful post-mold handling. Here’s a look at the challenges of micro-molding with LSR and what makes it different from thermoplastic micro-molding.

Read More