Sumitomo (SHI) Demag North America Names New Executive Leadership

The company has appointed Liam Burns to serve as president and John F. Martich III to serve in the expanded role of chief operating officer.

(left to right) John F. Martich III, Liam Burns and Beth Belay. Source: Sumitomo Demag North America

Sumitomo (SHI) Demag North America has announced new executive leadership appointments, effective April 1, with Liam Burns named president, while John F. Martich III has accepted the expanded role of chief operating officer (COO).

Burns has been with the company for the past two years, serving as senior manager for northeast regional sales. Prior to joining the company, he was involved in the injection molding industry for 36 years, gathering experience in both managerial and technical positions.

In his new role, Burns will focus on external initiatives, driving customer value, strengthening partnerships and elevating the global Sumitomo (SHI) Demag brand messaging across North America. The company says customer-centric strategies and market expansion will underline this strategy to support the company’s long-term growth.

“Innovation and customer excellence have always been central to Sumitomo (SHI) Demag's global success,” Burns says. “I’m honored to take on this role and build on our strong foundation. I look forward to connecting with our customers, gaining deeper insights into their needs, and working together to shape the future of our industry.”

Martich has been serving as executive vice president since 2023. With his new COO role, he will oversee internal operations to ensure efficiency, innovation and complete alignment with the company’s global strategic objectives. Collaborating closely with Beth Belay, corporate controller and compliance officer, Martich is focused on enhancing operational excellence and optimizing 大象传媒 processes.

“With this dynamic leadership team in place, Sumitomo (SHI) Demag North America is well-positioned to expand its market influence and international reach by continuing to provide innovative solutions to the plastics manufacturing industry,” says Anatol Sattel, Group CSO.

Sumitomo (SHI) Demag specializes in injection molding machines for plastics processing. The global development and production network of Sumitomo Heavy Industries and Sumitomo (SHI) Demag includes four facilities in Japan, Germany and China with more than 3,100 employees. The product portfolio includes all-electric, hybrid and hydraulic injection molding machines with clamping forces of between 56 and 1,700 tons. With more than 167,000 installed machines, Sumitomo (SHI) Demag is present in important global markets and making it one of the largest manufacturers of injection molding machines in the world.

At Sumitomo’s headquarters in Chiba, Japan, the company manufactures machines with clamping forces in the small to medium range. Nearly 95% of all delivered machines are equipped with an all-electric drive concept. Sumitomo (SHI) Demag’s German facilities in Schwaig and Wiehe produce the Systec Servo range with hybrid drive as well as the El-Exis SP and Systec SP range of high-speed, high-performance machines. The all-electric IntElect range for international customers is also being produced in Germany.

As early as 1998, Sumitomo (SHI) Demag set up its first production site in Ningbo/China. In 2015, the Chinese subsidiary Demag Plastics Machinery (Ningbo) Co., Ltd. installed a new facility with a 13,000 m² floor space. It is earmarked for the production of the Systec C range with clamping forces of between 56 and 1,100 tons for the Asian market.

In addition to injection molding machines, the company also offers customized and standardized systems for part handling automation, technical and process solutions for special applications, tailored services and service concepts as well as a range of financial options to support investment in injection molding machines.

Related Content

PHA Compound Molded into “World’s First” Biodegradable Bottle Closures

Beyond Plastic and partners have created a certified biodegradable PHA compound that can be injection molded into 38-mm closures in a sub 6-second cycle from a multicavity hot runner tool.

Read MoreUS Merchants Makes its Mark in Injection Molding

In less than a decade in injection molding, US Merchants has acquired hundreds of machines spread across facilities in California, Texas, Virginia and Arizona, with even more growth coming.

Read MoreHow to Extrusion Blow Mold PHA/PLA Blends

You need to pay attention to the inherent characteristics of biopolymers PHA/PLA materials when setting process parameters to realize better and more consistent outcomes.

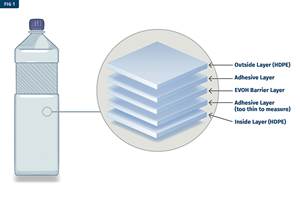

Read MoreMeasuring Multilayer Plastic Containers Made Easier With Today's Ultrasonic Gauges

Ultrasonic gauge technology has evolved to simplify measurement of very thin layers in plastic containers. Today’s gauges with high-frequency capabilities and specialized software can make multilayer container measurement quick and easy for ordinary users.

Read MoreRead Next

Adaptive, Automatic Process Control for Injection Molding

Sumitomo (SHI) Demag says its activeMeltControl for all new IntElect 2 machines can automatically compensate for shot-weight variations.

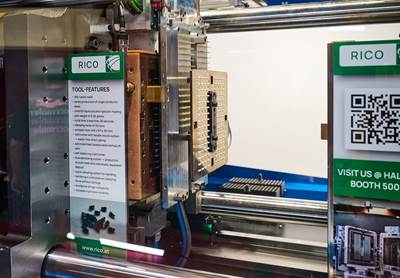

Read MoreLSR Advances in Dispensing, Tooling and Automation

At Fakuma 2023, Sumitomo (SHI) Demag’s LSR injection molding machines showcased advances from itself and partners Reinhardt-Technik, Rico and Sepro.

Read MoreAll-Electric IMM Advances for Packaging, Medical and LSR

NPE2024: Sumitomo SHI Demag’s show focus is on the application of all-electric injection molding machine technology for a variety of markets and components.

Read More