Molds & Tooling for Plastics Production

Molds and tooling for plastics production are used in all processes to give the melted plastic its final shape. Includes molds, mold components, ejector pins, mold bases, nozzles, mold cores, mold cavities, mold texturing, laser marking.

Narrow Your Molds & Tooling Search

ESSENTIAL READING

VIEW ALLAIM Institute Continues to Grow Plastics Education and Training on 10th Anniversary

The AIM institute was created in response to the rising need for skilled injection molding professionals, providing individuals with a fundamental understanding of plastic rheology and plastic flow through a mold.

Read MoreWhere and How to Vent Injection Molds: Part 3

Questioning several “rules of thumb” about venting injection molds.

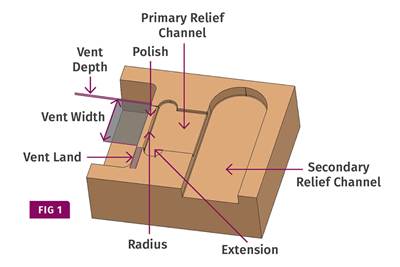

Read MoreBack to Basics on Mold Venting (Part 2: Shape, Dimensions, Details)

Here’s how to get the most out of your stationary mold vents.

Read MoreBack to Basics on Mold Venting (Part 1)

Here’s what you need to know to improve the quality of your parts and to protect your molds.

Read MoreMold Maintenance, Tooling Know How

The ability of technicians in an injection molding shop to fix, modify or upgrade a mold has a huge impact on that company’s bottom line. With this collection of content, we’ve bundled some of the very best advice on repairing and maintaining injection molding machines.

Read MoreHow to Achieve Simulation Success, Part 2: Material Characterization

Depending on whether or not your chosen material is in the simulation database — and sometimes even if it is — analysts will have some important choices to make and factors to be aware of. Learn them here.

Read MoreLatest Molds & Tooling News And Updates

AIM Institute Continues to Grow Plastics Education and Training on 10th Anniversary

The AIM institute was created in response to the rising need for skilled injection molding professionals, providing individuals with a fundamental understanding of plastic rheology and plastic flow through a mold.

Read MoreMouldpro Mold Maintenance Tools, Gate Cutters Enable Improved Productivity

Mouldpro offers a variety of soft tools and gate cutters that are constructed to ensure molders can safely work on mold tools without damaging the mold surface.

Read MoreHeated Sprue Bushing Line Expanded

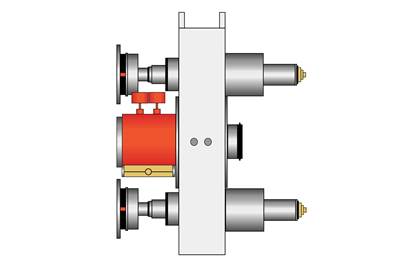

The company says the assemblies are designed to minimize pressure loss and enable rapid gate freeze.

Read MoreExpanded Blade Ejector Line

Progressive Components has expanded its blade ejector line, which includes optional “Mold-Ready” features that reduce the need for in-house machining.

Read MoreU-Frame and Companion Insert System Expanded

PCS Company is introducing new sizes for its Flexible Insert Tooling System (F.I.T.S.) offering in support of prototyping, sampling and short production tooling.

Read MoreEjector Delay Unit for Two-Stage Demolding

Hasco’s Z1725/… ejector delay unit enables two-stage ejector demolding so sprue and part are cleanly separated through a coordinated ejector movement.

Read MoreFeatured Posts

The Connector Conundrum: 3D Printed Mold Tooling’s Role in Innovation

ReelView Fishing faced an electronics obstacle in the development of its new technology for underwater video. Additive manufacturing for moldmaking allowed for the speed necessary to iterate to a solution. How inventors and invention will benefit from new ways of obtaining production-ready tooling.

Read MoreDesign Your Tools for Moldability ... and Maintenance

In the initial design phase, when considering the structure and elements of the tool, are you designing them to be maintenance friendly? Canon Virginia has used this approach and preventive maintenance to make tool replacement a thing of the past. You can, too. Here’s how.

Read MoreGet Better at Using Foam for Your Molded Parts

Machine performance and process speeds are critical when using foam to reduce part weight while retaining part integrity.

Read MoreScaling New Heights With Vertical Integration

Eden Manufacturing was founded on a vision of vertical integration, adding advanced injection molding capabilities to a base of precision moldmaking and more recently bringing Swiss-type machining capabilities in-house.

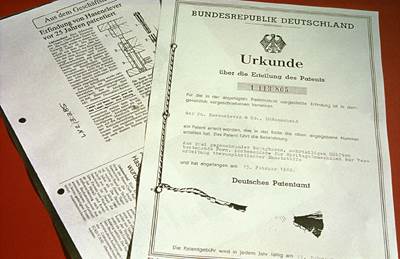

Read MoreHasco Marks a Century in Mold Components, Mold Bases and Hot Runners with Cake and New Technologies

NPE2024: Cake, drinks and the unveiling of a new North American website providing online ordering in the U.S. and Canada for the first time are just some of the things happening at Hasco’s booth as it brings its year-long centennial celebration to Orlando.

Read MoreMedical Molder, Moldmaker Embraces Continuous Improvement

True to the adjective in its name, Dynamic Group has been characterized by constant change, activity and progress over its nearly five decades as a medical molder and moldmaker.

WatchFAQ: Molds & Tooling

Leader pins are often referred to as guide pins. They lead or guide one-half of a mold into the other. The outer diameter of a leader pin is typically 0.0010 in. below nominal with a tolerance of +0.0000/-0.0005 in. A leader-pin bushing typically has an inside diameter of 0.0005 in. above nominal with a tolerance of +0.0005/-0.0000. Therefore, the pin has a close sliding fit in its mating bushing with a clearance of between 0.0015 and 0.0025 in. total. A close sliding fit is intended for the accurate location of parts that must assemble without perceptible play.