New Research from Essentium Shows Need for Additive Manufacturing Education

Even as the industry moves towards large-scale AM, 28% of manufacturers reported their personnel lacked additive manufacturing skills.

Essentium announced the third in a series of findings from independent global research on the current and future use of industrial 3D printing. The survey found an increasing need for more education, skills, and training across manufacturers’ organizations. Even as the industry moves towards large-scale AM, 28% of manufacturers reported their personnel lacked AM skills.

The survey highlighted continued optimism among manufacturing executives in the potential of industrial-scale 3D printing to save billions in manufacturing costs [90% agree], drive competitive advantage [84% agree], and economic advantage [85% agree].

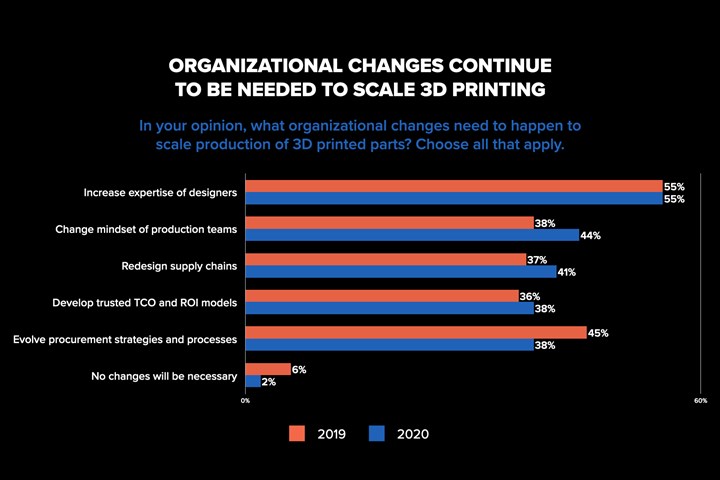

The research showed that realizing this vision requires change and development throughout the workforce, from designers and engineers to finance and procurement. The top needed organizational change cited was the expertise of designers [55%], followed by a shift in mindset by production teams [44%], and evolving procurement strategies [38%].

Almost a third of respondents [29%] said they wanted their finance teams to develop a deeper understanding of AM’s cost and value implications, while 26% said it was important to re-educate procurement teams on buying materials for 3D printing rather than focusing on the assets of components.

“Realizing the true value of industrial-scale additive manufacturing is highly dependent on a skilled manufacturing workforce that has the expertise to hone, advance, and support AM processes,” said Blake Teipel, CEO of Essentium. “We are supporting customers, partners, and universities as they respond to this urgent industrial need for an AM-ready workforce primed to transform the world of manufacturing and the products it creates for both competitive and economic advantage.”

Research findings from Essentium reveals that, as manufacturers move towards large-scale AM, almost a third reported their personnel lacked AM skills.

Related Content

-

How 3D Printing Supports Toolmaking Workforce at This Multiscale Molder

At more than a century old, General Pattern has seen multiple evolutions in its 大象传媒 — the latest of which is the embrace of additive manufacturing technologies for mold tooling and beyond.

-

Additive Technologies for Injection Mold Tooling Ride Tailwinds

NPE2024: Lowering barriers to additive manufacturing adoption in toolmaking.

-

KraussMaffei Nears Completion of Corporate Headquarters Move

The 185-yr old German maker of plastics processing machinery is shifting to a more than 200,000-m2 greenfield site in Parsdorf.