Improve Quality & Productivity With Advanced Screw Design

Most molders are still running with screw designs that haven’t changed much in 30 years. But they don’t need to.

In November 2020 as part of its , Plastics Technology hosted a session on “Establishing & Maintaining a Robust Molding Process,” in which I participated. During this webinar there was a short discussion on new injection molding machines, which spurred a conversation about screw design and melt uniformity, one of my pet topics within the molding industry.

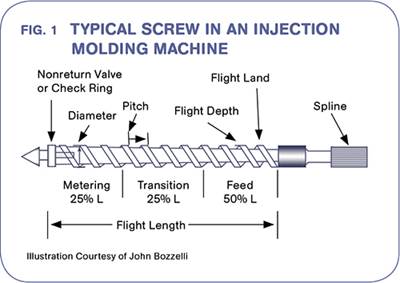

FIG 1 Melt model of a general-purpose injection screw.

One striking comment during this webinar was made by Mike Durina, a respected injection molding innovator who runs his own company, MD Plastics. Mike noted that most molders are still relying on “general-purpose” screw designs that go back 30 years. With all of the technical improvements that have been made on machines over that time, nothing has been done to improve melt uniformity. We still use “general-purpose” (GP) screws, which well-known screw designer Bob Dray wisely has called “no-purpose” screws. That is they do not melt plastic uniformly. Processing with a uniformly melted plastic would seem like a high priority, but it has seen little if any attention. This needs to change.

Melt Uniformity

Why is melt uniformity important? Well, you would be hard-pressed to name a single common molding/part problem that melt non-uniformity does not cause or exacerbate. To name a few:

1. Weak weld lines;

2. Part failures/performance issues;

3. Warping;

4. Non-uniform filling;

5. Marbling (color swirls/blotches);

6. Resin degradation, black specks;

7. Long color-change times;

8. Short shots;

9. Frequent screw cleanings;

10. Longer cycles.

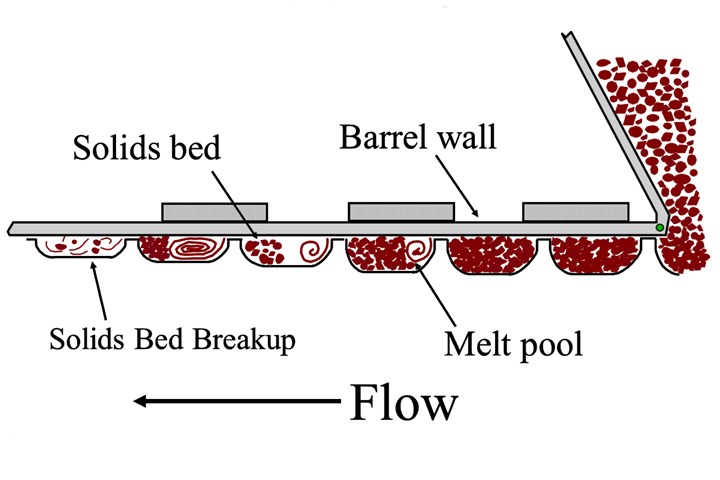

FIG 2 Degraded polymer at junction of flight and root diameter of a general purpose screw indicates dead space.

So what does it take to get melt uniformity? Start with a melt model of a GP screw shown in Fig. 1. As shown, all of the pellets often do not melt, and the resulting solids-bed breakup provides for poor mixing and degradation (as well as causing the problems listed above). Also, it is common for the plastic in areas where the flights mate with the root diameter to stagnate and degrade. Figure 2 shows the typical polymer degradation often seen when a screw is pulled for cleaning or repair. While I do not have actual stats, my experience is that a minimum of 50% to 80% of all machines running today exhibit this problem. Even if it is only 25%, it still rates as a major problem in our molding industry. Why does the industry put up with this? Do you have to put up with this?

FIG 3 In this barrier screw, note green polymer still in the barrier flight, even after purging. This indicates dead space. (Photo: Joe Cascarano)

Alternative Designs

The fact is that the industry does not have to use GP screws. There are solutions, but be careful who you talk to. When anyone begins to ask machine suppliers and most screw manufactures about these problems, the knee-jerk response is, “Try our barrier screw.” Proceed cautiously. Figure 3 shows a typical barrier type screw after it was purged. Note the green polymer is still in the barrier flights. Since this is after purging, you can understand that this material stays there during production and will degrade with time. You will get even more degradation and black specks. So, if barrier screws are not the answer, what is?

FIG 4 Melt-uniformity screw.

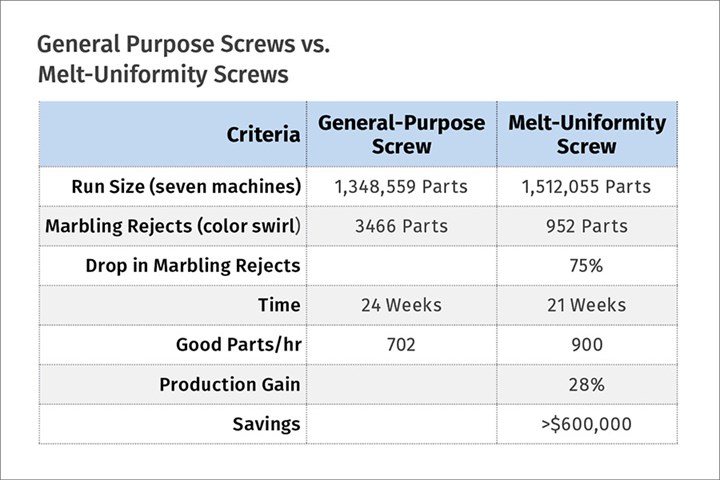

Back in the late 1980s I was fortunate enough to have worked on a company-sponsored research program to solve problems of mixing color concentrates into natural resins. After spending one-and-a-half years and over $200,000 on around 10 different barrier screw designs that did not work, we developed a melt-uniformity screw (Fig. 4). It was not a barrier screw. This “melt uniformity” screw passed rigorous instrumental requirements for color distribution and uniformity. Further we trialed it in seven different production machines making complex parts for six months. The results were impressive (see accompanying table).

The data speaks for itself. Replace your general-purpose screws with melt-uniformity screws. You will save time, make your life easier on the shop floor, and make significantly more money.

Not convinced? Mike Sepe, a noted materials expert and fellow Plastics Technology columnist, actually purchased one of these screws when he worked for a molder. He wrote about his experience in an April 2012 column check out what Sepe has to say about it: “When we put in the new screw the melt temperatures were reduced by 60º F and the backpressure came down from 300 psi to 75 psi hydraulic. The problems with color incorporation and unmelt disappeared; the cycle time was reduced; and the periodic screw cleanings stopped. The screw paid for itself in seven months and started a revolution within the operation that eventually saw general-purpose screws replaced with mixing screws throughout the plant. The number of ‘material problems’ and ‘processing problems’ that simply disappeared was a revelation.”

Only one major problem: Today, I cannot find a shop to make this design properly. Believe it or not, I took a print to a screw shop in Michigan and their response was, “No, we will not make it…a high-school student could do a better design.” Seriously, if anyone knows of a good small shop that makes screws, let me know. I need to replace what I have.

About the Author

John Bozzelli is the founder of Injection Molding Solutions/Scientific Molding in Midland, Mich., a provider of training and consulting services to injection molders, including LIMS, and other specialties. Contact john@scientificmolding.com.

Related Content

Fundamentals of Polyethylene – Part 6: PE Performance

Don’t assume you know everything there is to know about PE because it’s been around so long. Here is yet another example of how the performance of PE is influenced by molecular weight and density.

Read MoreWhat You Need to Know About Leader Pins and Bushings

There’s a lot more to these humble but essential mold components than you might suspect. Following the author’s tips could save much time, money and frustration.

Read MoreWhere and How to Vent Injection Molds: Part 3

Questioning several “rules of thumb” about venting injection molds.

Read MoreThree Key Decisions for an Optimal Ejection System

When determining the best ejection option for a tool, molders must consider the ejector’s surface area, location and style.

Read MoreRead Next

Working with Color Concentrates

Industry needs more development of enhanced-mixing screws.

Read MoreScrews and Pellets: One Size Does Not Fit All

Screw design, pellet type/size and material behavior are all critical issues to consider to deliver uniform melt to the mold.

Read MoreRethinking the Injection Screw: Is It a Trend?

Renowned screw designer Robert F. Dray wrote to me recently, lamenting that injection molding screw design has not received the kind of attention that the extrusion industry has paid to perfecting this fundamental processing component.

Read More.jpg;width=70;height=70;mode=crop)