Know-How

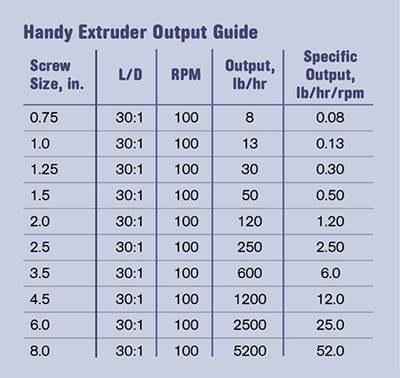

Get Smarter on Extruder Sizes

Processors tend to recommend a much larger extruder than what鈥檚 really necessary for the job and the capabilities of the downstream equipment.

Read MoreShould You Profile Injection Velocity?

If you can get by with one velocity, use only one, because fill time is easier to reproduce, and it is easier to set up the process.

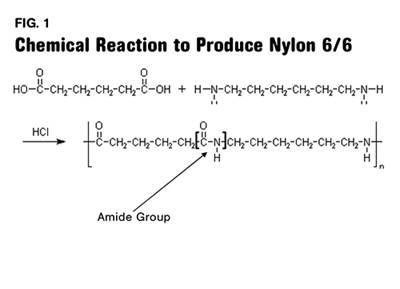

Read MoreWhen It Comes to Nylon, Don’t Do the Math

Chemistry is seldom as simple as it looks. Polymer chemistry takes the complexity up a notch. Nylon chemistry is about much more than doing the math.

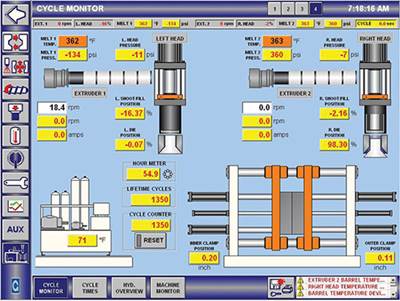

Read MoreMonday Morning Start-Up Of Accumulator Head Machines

A good way to achieve plantwide consistency on restarts is to establish a blow molding checklist based on the items discussed here, as different operators may be performing these steps at various times.

Read MoreWhat’s the Deal With High-Speed Extruders?

If we are talking about extruder screw speed, how about 1800 rpm? That鈥檚 how fast some extruders are running today.

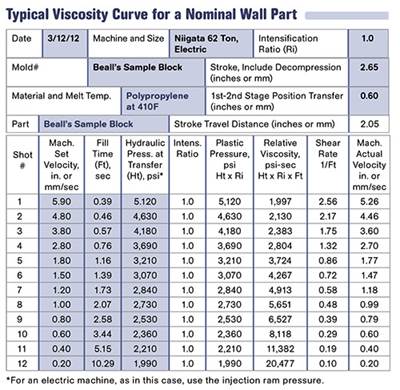

Read MoreUnderstanding Polymer Flow: Interpreting the Viscosity Curve

Take the time to do the viscosity curve on new molds. You will learn more in that hour than many learn in years about the process for this tool.

Read MoreBiopolymers: Time to Take A Deep Breath

Are we looking at all of the implications associated with developing this new 'crop' of polymers?

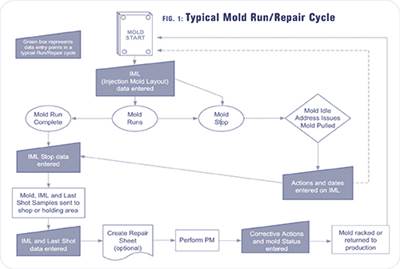

Read MoreThe Value of 20 Bits of Data

With these 20 bits of data, toolrooms can drastically lower the cost of keeping molds running and improve mold reliability and tooling life while reducing breakdowns and molding better parts.

Read More