Know-How

Melt Flow Rate Testing – Part 2

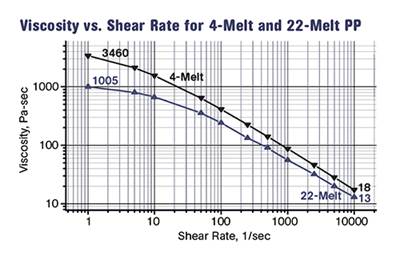

To fully appreciate the strengths and weaknesses of the melt-flow-rate (MFR) test it is important to know something about the way the test is performed.

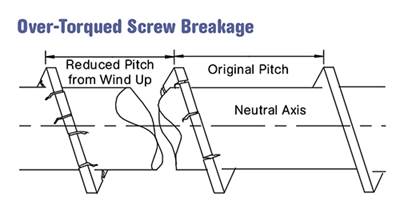

Read MoreUnderstanding Screw Breakage

You might think you're over-torquing the screw, but more often than not bending is the reason.

Read MoreLevel Your Press in an Hour or Less

A level injection molding machine is necessary to keep producing high-quality parts. Here's how to do it right.

Read MoreYour Pre-Installation Checklist-Part 1

The work really begins after you've ordered your new machine.

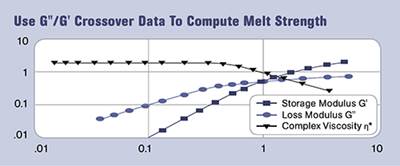

Read MoreExtrusion: Where's the Data? The Importance of Melt Strength in Extrusion

All extrusion processes depend to some degree on the melt strength of the polymer, and this property is generally a no-show on data sheets.

Read MoreWhat's Different About Molding Engineering Plastics

If you try to run them like commodity materials such as PP you'll have problems.

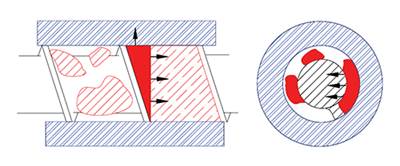

Read MoreThe Cause of Catastrophic Screw Wear

Erratic feeding can be the culprit. This is not uncommon when dealing with recycled material.

Read MoreTake a Scientific Approach to Troubleshooting

Taking a scientific approach minimizes the 'art' of molding, which is particularly helpful when troubleshooting

Read MoreDimensional Stability after Molding—Part 5

All materials possess a property called the coefficient of thermal expansion (CTE). The vast majority of materials increase in size as their temperature increases and decrease in size as their temperature declines.

Read More