Know-How

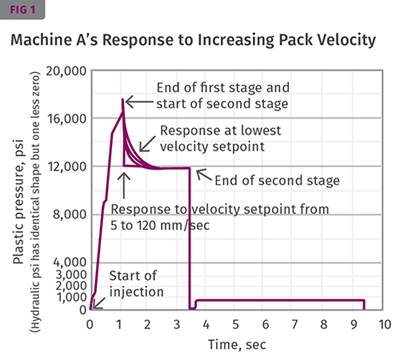

INJECTION MOLDING: How Does Your Machine Control Pack Velocity?

You’ll need to find out in order to develop a molding process that you can repeat from machine to machine and mold to mold.

Read MoreMATERIALS: Don’t Guess Your Way through Root Cause Analysis: Part 2

The huge chasm between the laboratory and manufacturing discipline usually does not lend itself to problem-solving. It can be improved with clear communication between the analysis laboratory and the people bringing the problem to the lab.

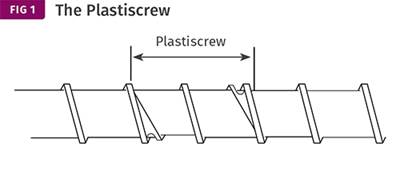

Read MoreBLOW MOLDING: The Role of Screw Design in Industrial Blow Molding

Screw design is seldom discussed when buying a new machine. In fact, it should be near the top of the list.

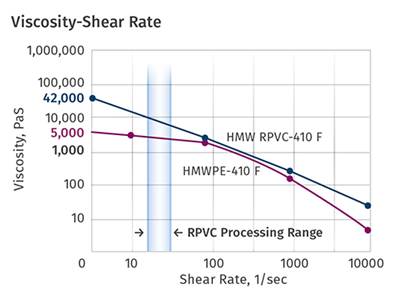

Read MoreEXTRUSION: Why Barrier Screws & Rigid PVC Don’t Always Mix

RPVC’s somewhat unusual melting mechanism makes it unsuited to traditional barrier type designs.

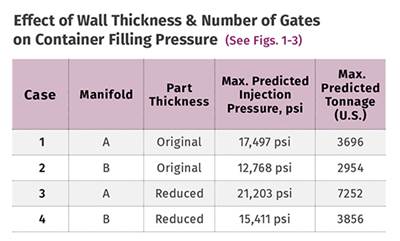

Read MoreINJECTION MOLDING: The Importance of Nominal Wall For Lightweighting Molded Parts

Establishing a nominal wall is one of the most important decisions an engineer makes when designing parts. Understanding how design changes will impact the manufacturing process is critical to ensure the part performs as expected.

Read MoreMATERIALS: Don’t Guess Your Way Through Root Cause Analysis

More than 50 different polymer test techniques can be used to find root causes of problems. Of these, five or six are fairly common. Use them to take the guesswork out of why a product failed.

Read MoreEXTRUSION: Processing Rigid PVC? Know Your Rheology

Before choosing and sizing extruders for running rigid vinyl, it is wise to bone up on the viscosity behavior of the material.

Read MoreMATERIALS: Performance in Polyethylene: Density Matters: Part II

Remembering the case of the failed gas tanks.

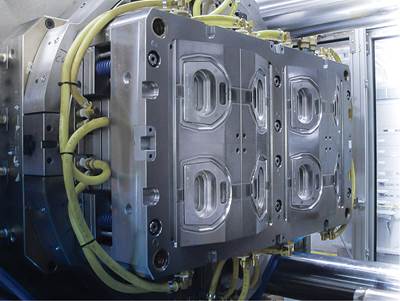

Read MoreTOOLING: Balancing the Heat Budget In Injection Molds

Basic formulas for how much heat you must pull out of the mold to achieve a set cycle time

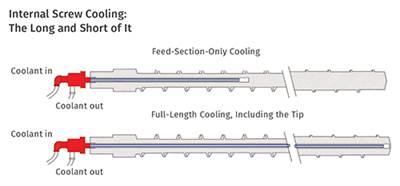

Read MoreEXTRUSION: When Internal Screw Cooling Makes Sense

Internal screw cooling could help you solve solids-feeding and burning problems.

Read More