Know-How

INJECTION MOLDING: How to Specify an Injection Molding Machine

In part two of a three-part series, the focus is on the injection unit.

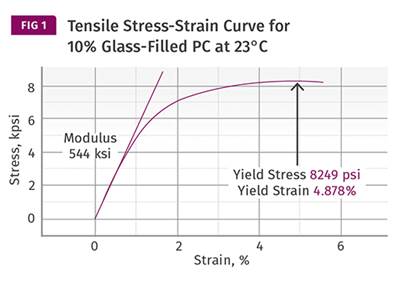

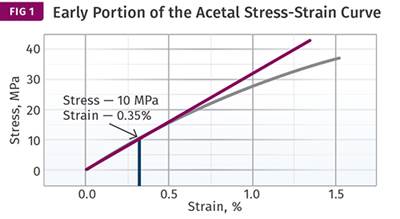

Read MoreMATERIALS: The Problems with Single-Point Data

Engineers who are used to working with metals are surprised that plastics cannot operate as close to their yield points as can metals. The yield point is not enough to tell you how the material reacts to stress.

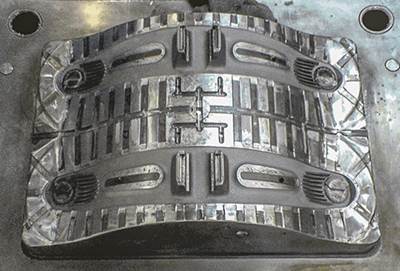

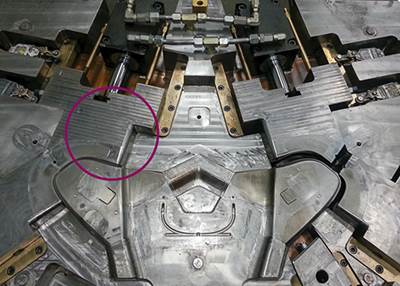

Read MoreTOOLING: Venting: Where And How Deep?

After last month’s introduction to the subject, let’s get into the details on vent depths, land lengths, and the alternatives to perimeter venting.

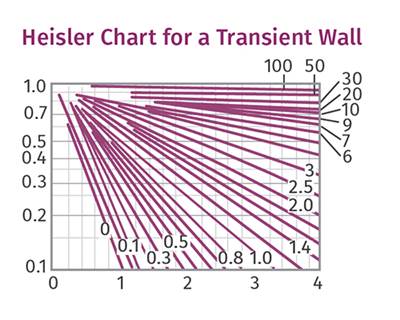

Read MoreEXTRUSION: Cooling: The Critical Function in Extrusion

Figuring out how much cooling your process needs is complicated. But there are ways to approximate.

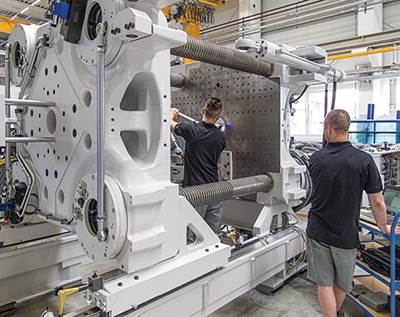

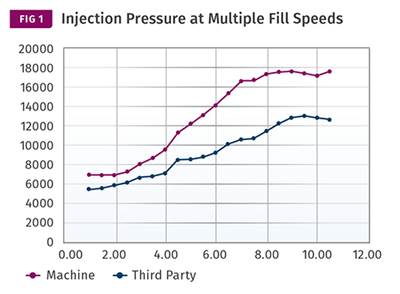

Read MoreINJECTION MOLDING: How to Specify an Injection Molding Machine

With the market percolating, more molders are looking at new presses. This series will discuss what you should consider before writing a check, beginning with the clamping unit.

Read MoreMATERIALS: The Problems with Single-Point Data

Properties are generally provided at a single temperature on a data sheet. But do those properties stay the same with changing temperatures? Of course not.

Read MoreTOOLING: Venting: A View From the Trenches

Venting is a prime culprit for molding problems, partly because toolmakers and process techs have different ideas of what’s needed.

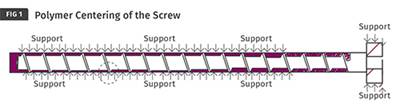

Read MoreEXTRUSION: Here’s Why You Shouldn’t Run Your Extruders Dry

At least not for longer than a few minutes. The thin film that’s captured between the screw flights and barrel wall supports the screw and acts as a lubricant. Without it, galling can occur.

Read MoreINJECTION MOLDING: Scientific Molding Gone Wrong

Sometimes molders get trained in Scientific Molding only to revert to their old way of doing things as soon problems pop up.

Read MoreMATERIALS: The Trouble with Data Sheets

Data sheets are routinely relied upon, yet the data they provide is limited in scope and can lead to incorrect conclusions.

Read More