Know-How

INJECTION MOLDING: Develop Guidelines—Not Strict Procedures— For a Robust Molding Process

‘Fool-proof’ dos and don’ts will prove foolhardy in a process with so many variables. You aren’t slinging burgers.

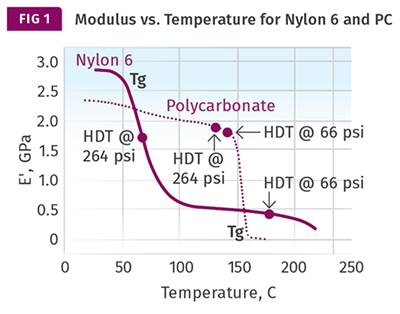

Read MoreMATERIALS: The Problems with Single-Point Data, Part 7

The industry can choose between continuing to perform DTUL tests that provide single points that are part of a curve never seen, or perform the test that provides the entire curve.

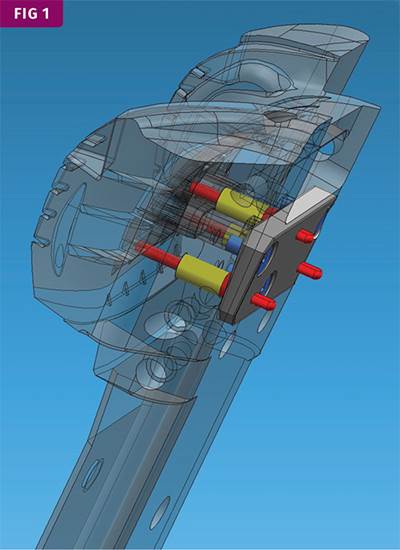

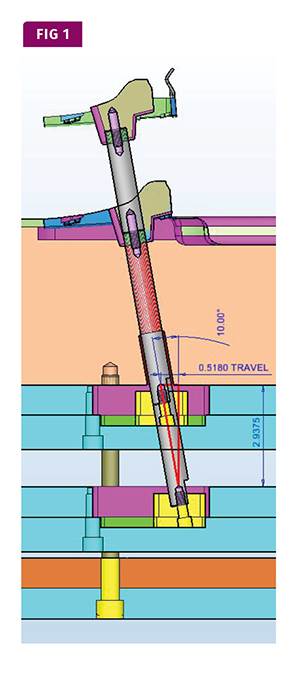

Read MoreTOOLING: Dealing with Lifters--Part 2

This installment delves into more detail on some variables of design and fitting/timing of the lifters, which can cause issues or failures during molding.

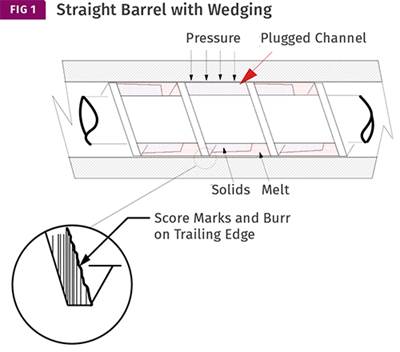

Read MoreEXTRUSION: The Two Main Causes of Screw Wear

Wedging and misalignment are often confused with each other when inspecting a worn screw.

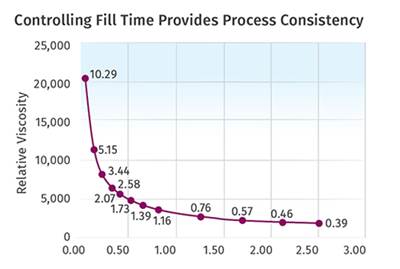

Read MoreINJECTION MOLDING: Gate-Seal Testing Done Right

Follow these 16 steps to perform the experiment and learn what is best for your part and process.

Read MoreMATERIALS: The Problems with Single-Point Data--Part 6

Data sheets can be limited in the information they provide on how the material performs at elevated temperatures.

Read MoreTOOLING: Having Trouble with Lifters?

Lifters can cause tool maintenance, repair, and processing issues if not designed properly. Here we begin a series on how to avoid all this.

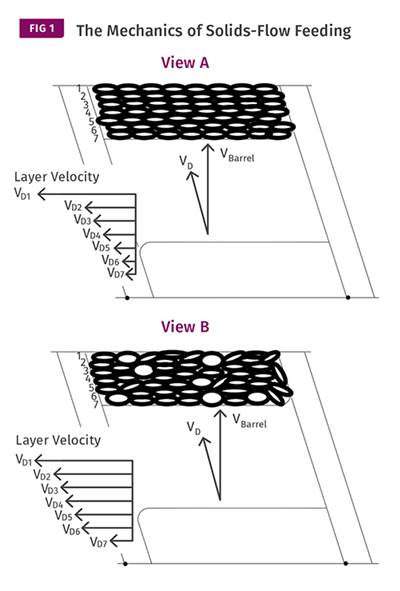

Read MoreEXTRUSION: Pellet Geometry Can Impact Output

A simple angle-of-repose experiment can help you determine how your pellets will feed.

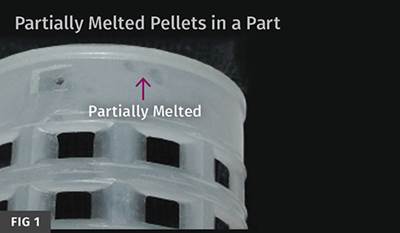

Read MoreINJECTION MOLDING: Why Pellet Size and Shape Are Important

Uniformity is needed to help ensure melt quality.

Read MoreMATERIALS: Impact Testing: The Problems With Single-Point Data

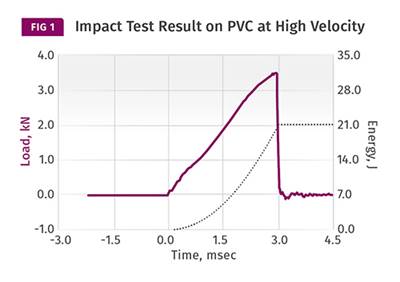

Knowledge of test conditions and graphical data showing the course of the impact event can help provide engineers and designers with the information they need to make informed choices about material toughness.

Read More