Know-How

RECYCLING: Recycling’s ‘Vision’ of the Future

Optical sorting technology continues to help push advances in plastics recycling.

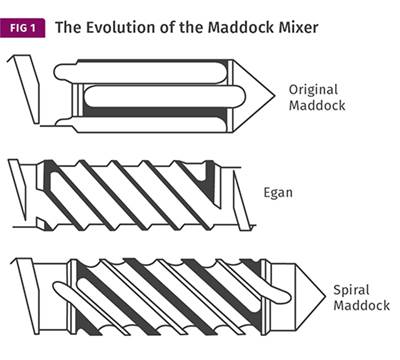

Read MoreEXTRUSION: Barrier Screws and Mixers

For some reason, there are a lot of barrier screws in operation with high-shear mixers, when a distributive mixer is usually a better choice.

Read MoreUnderstanding Machine vs. Plastic Variables

Why setup sheets, DOEs, validations, etc. may not yield the results they should.

Read MoreMATERIALS: The Problems with Single-Point Data

In plastics, notched Izod and Charpy test results have been complicated by the way they are reported.

Read MoreExtrusion: How to Adjust for Polymer Shrinkage and Orientation

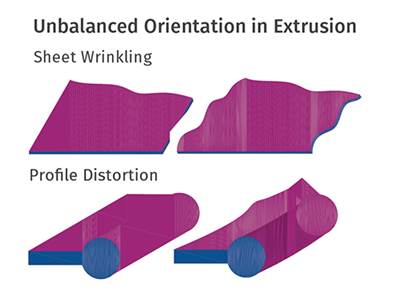

Polymers shrink and orient. Sometimes orientation is unbalanced, resulting in misshaped parts. But there are steps beyond tweaking the die that can mitigate these effects.

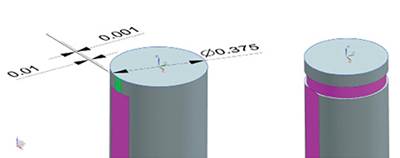

Read MoreINJECTION MOLDING: How to Specify an Injection Molding Machine

There are 51 things to consider when spec’ing a controller.

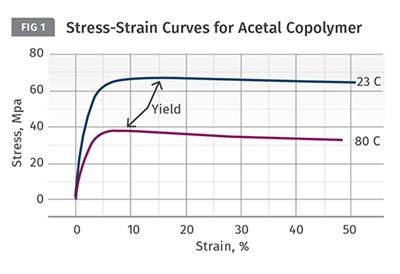

Read MoreMATERIALS: The Problems With Single-Point Data

Polymer properties are not constant as a function of temperature, and even small temperature changes can affect properties.

Read MoreRECYCLING: Compatibilizers Create New Recycle Feedstream Value

Generally confined to prime material applications, these additives are helping recyclers improve yields of mixed-material bales.

Read MoreTOOLING: How to Vent Mold Details

Principles to follow in venting bosses, ribs, pins, cores, slides, and lifters.

Read MoreEXTRUSION: Another Technique for Controlling Melt Temperature

Flight widths are almost always designed at 10% of the screw diameter. But they can be optimized to reduce melt temperature and perhaps boost output.

Read More