Know-How

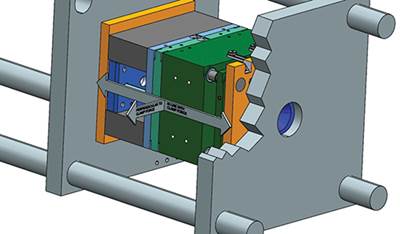

High-Pressure Water: A New Concept for Screw Cleaning

Everyone in a molding plant is on the same page for screw cleaning: Avoid pulling it until there is no alternative. Here are ways for dealing with the inevitable, including an altogether new technique.

Read MoreThe Mystery of Physical Aging, Part 2: Slow Down Aging

Dimensional and property changes depend on the size of the part, molecular weight of the resin, and processing conditions.

Read MoreNew Extrusion Equipment Combines U.S. Management with Chinese Production

Starting up in 2011, Uway Extrusion has begun its commercial push this year, with plans to exhibit at NPE2015 next March.

Read MoreAutoma Acquired Out of Liquidation By Fellow Italian Firm

The Italian manufacturer of blow molding machinery has been acquired by a fellow Italian company, which services, rebuilds and sells used blow molding machines.

Read MoreTOOLING: Flash-Free Molding: Part Two

Parting-line maintenance, mold spotting, and machine conditions can all contribute to flash.

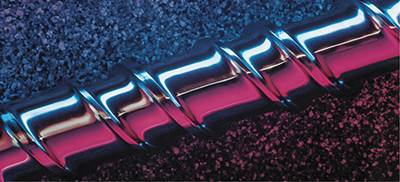

Read MoreEXTRUSION: Why Bother to Chrome Plate Your Screws?

It doesn’t add that much to the overall cost and can improve performance and facilitate maintenance. So the better question is: Why not?

Read MoreINJECTION MOLDING: How to Tell If Your Non-Return Valve Is Leaking

Check valves are potentially troublesome devices. Here’s how to find out if yours is behaving properly.

Read MoreThe Mystery of Physical Aging, Part 1: Knowing the Difference

In polymers, aging is commonly considered essentially synonymous with oxidation. But there are important differences between this type of chemical aging and less commonly recognized physical aging. Let’s unlock the mystery.

Read MoreTOOLING: Flash-Free Molding: Part 1

A robust process window relies a lot on tooling. So it stands to reason that making a tool change to address issues provides a more robust solution

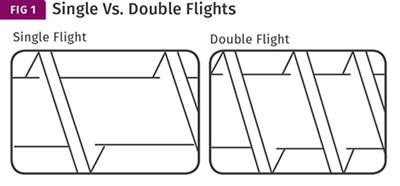

Read MoreEXTRUSION: Double Flights Are Not a Cure-All

There are certain applications where double-flighted feed sections make sense, and others where they don’t.

Read More