Know-How

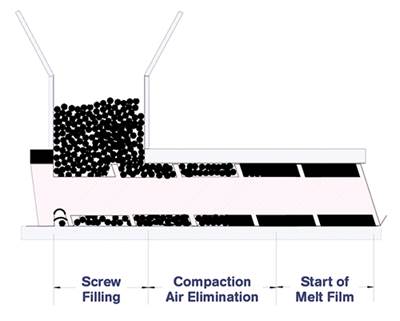

Don’t Overlook the Feed Section

Most extrusion screw designers often do not design the feed section with the same rigor as other sections. This is odd since nothing goes through the screw that doesn’t first go through the feed section.

Read MoreMelt Flow Rate Testing—Part 5

There are two points in the manufacturing supply chain where a determination of average molecular weight (MW) is important. The first is when the material is first received by the molder. The second is after molding.

Read MoreRegrind and Melt Pumps

Changing levels of regrind can result in unstable output. If not set up properly, a melt pump can add to this instability—the opposite of the intended effect.

Read MoreMelt Flow Rate Testing—Part 4

Few molders perform the test in-house. Of those that do, most don't understand why they are doing it or what they are measuring.

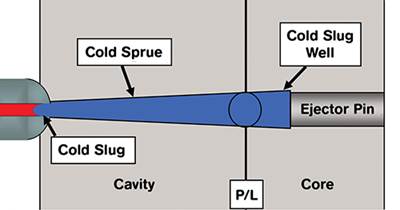

Read MoreDon’t Forget the Cold Slug Well

Its primary function—as the name suggests—is to act as a trap, or “well,” for the cold slug.

Read MoreMelt Flow Rate Testing—Part 3

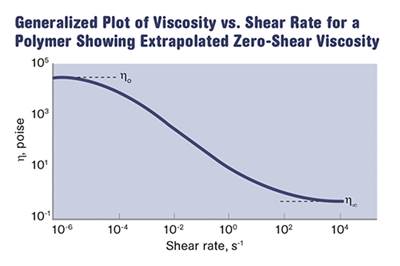

There is a well-established relationship between something called the weight-average molecular weight of a polymer and a parameter known as the zero-shear viscosity.

Read MoreYour Machine is Built…Now What?

Here is what you need to do to get ready for the installation of your new accumulator head machine.

Read MoreThe Scale-Up Conundrum

There are many methods used to determine scale-up based on output, but most designers do not scale the melting requirement along with the output.

Read More‘Auto Compensate’ Your Press To Handle Viscosity Variations

Here's how to put your injection molding machine on cruise control to make consistently good parts even in the face of material viscosity variations.

Read More