Know-How

PBT & PET Polyester: Part 2 The Performance Factor

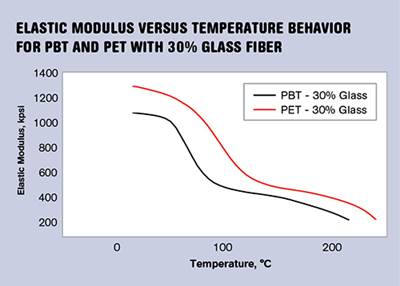

All things being equal, PET will outperform PBT mechanically and thermally. But the processor must dry the material properly and must understand the importance of mold temperature in achieving a degree of crystallinity that allows the natural advantages of the polymer to be realized.

Read MoreShutdown Tips For Accumulator Heads

Here's what you need to know to properly shutdown an accumulator head blow molding machine after a week running parts.

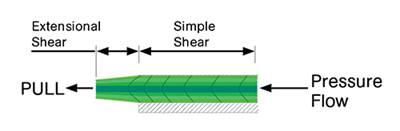

Read MoreNew Frontier for Single Screw R&D: Mixing & Melting by Extensional Shear

Extensional shear generally has been associated only with twin-screw extruders. However, I am now convinced it can be done with a single moving force (screw) by changing the geometry of the flow field perpendicular to the direction of flow.

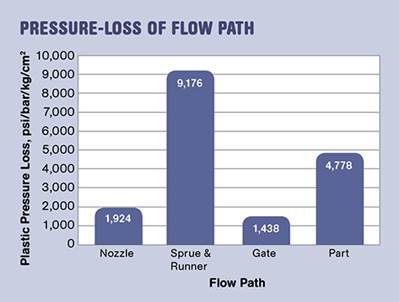

Read MoreGet the Most From Your Tooling

The history and culture of the molding industry has been to pull out every trick possible to work around design, resin, tooling, processing, and testing issues once the mold arrives. It is time to rewrite history.

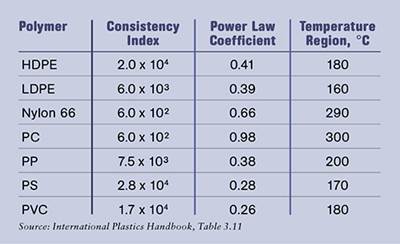

Read MoreThe Power-Law Coefficient

By referring to the power-law coefficient, the effect of barrel override in the metering section of many screws can be explained and anticipated.

Read MoreEstablish a True ‘24/7’ Production Process

New or existing mold trials need to produce a production-worthy process that will run 24/7.

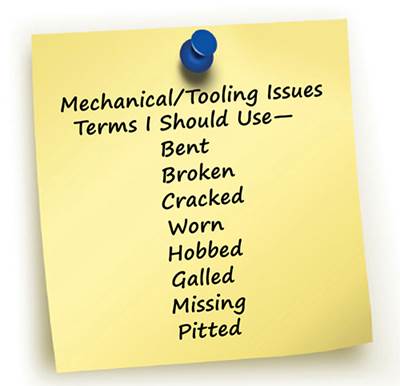

Read MoreMaintenance Terms of Endearment

Look closely at your company鈥檚 mold maintenance language and formalize your approach to create a clear and concise picture鈥攐ne that can be measured.

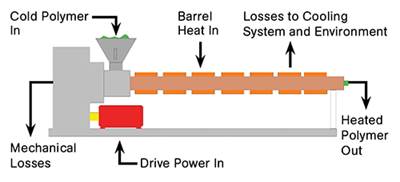

Read MoreMission (Nearly) Impossible: Estimating Extrusion Melt Temperature

Extrusion processors often ask screw designers to estimate the output and melt temperature of a new design in the works. Projected output of a new screw can usually be estimated fairly accurately. Melt-temperature estimate, however, is another story

Read MoreNozzle Leaks: Why They Occur, How to Detect & Fix Them

Nozzle leaks are a serious problem in injection molding. Here are some causes and remedies.

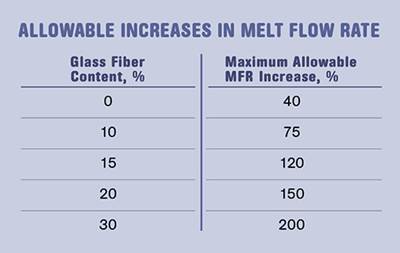

Read MoreUse MFR Cautiously with Filled Materials

If melt flow rate tests are used to evaluate the effect of processing on the average molecular weight of the polymer, the applicable rules must consider the contribution of the filler to the test result.

Read More