Know-How

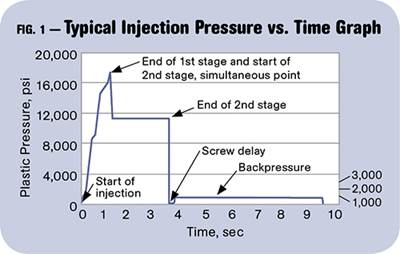

Improve Profits by Graphing Injection Pressure

Graphing is a powerful aid in optimizing the process and troubleshooting both process and machine issues.

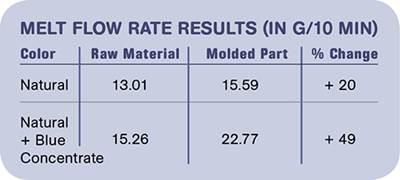

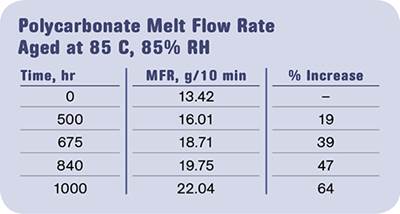

Read MoreWorking with Color Concentrates

Perhaps the greatest difficulty involving the use of color concentrates is specifying them appropriately for the material to which they are being added.

Read MoreSafety Sense in the Shop

Running a clean, organized, professional, and safe shop requires a team effort that includes an awareness of unsafe practices and equipment that need to be eliminated, replaced, or improved, along with the accountability of all to identify and document safety issues.

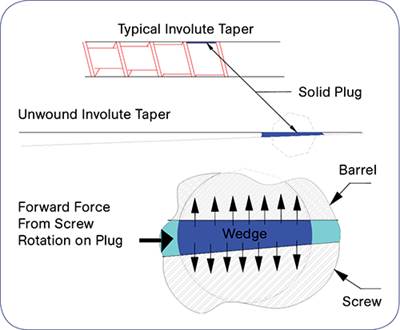

Read More‘Wedging’ Can Cause Severe Screw Wear

In a column I wrote for the July 2011 issue, I discussed the value of conducting “forensic” examination of worn screws when they are removed for clues to design flaws.

Read MoreWhat to Calibrate on Your Press

There are different approaches to meeting the goal of making parts identically. At the heart of all them is the process or the machine setup sheet. My bet would be you cannot find two that are identical.

Read MoreWorking with Color Concentrates

Because the consumer sees so many colored plastic articles, it is natural to assume that the process of achieving molded-in color is a simple one. Those of us in the industry know differently.

Read MoreWhy Multi-Cavity Molds Fill Unevenly

Balanced filling is critical for making identical parts, achieving high CPKs, holding tight tolerances, and getting “good” data from design of experiments.

Read MoreWhat Percentage of Barrel Capacity Should Your Shot Size Be?

The answer combines both experience and science, and it may be one of those molding details that gets overlooked but could be stealing a chunk of your profits.

Read More