Know-How

Injection Molding: How to Set Second-Stage (Pack & Hold) Pressure

Most molders work with two parameters for establishing second-stage pressure. But within Scientific Molding there are actually four.

Read MoreTooling: Setting Up Shop: Part III

Our last column covered shop size and bench requirements for a 50 x 50 ft mold-repair shop that will have a MPP (Mold Pull Pace) of approximately 25 to 30 multi-cavity molds a week and employ four repair technicians in a six-bench layout.

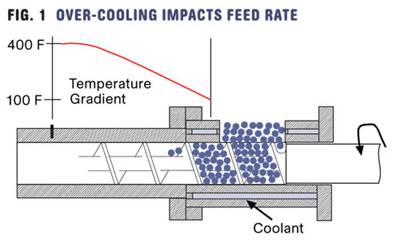

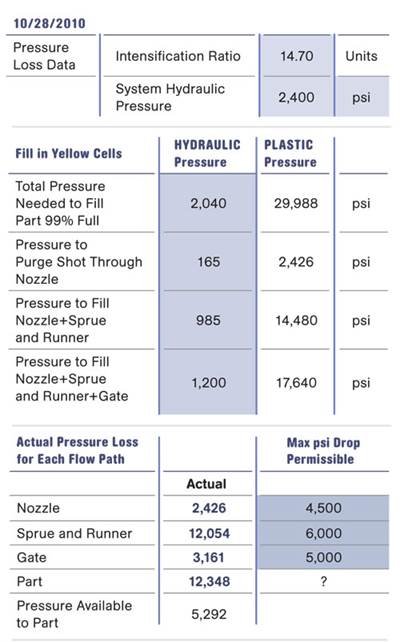

Read MoreInjection Molding: Understanding Pressure Loss In Injection Molding

One of the more prominent trends in processing is the need for higher plastic pressures to mold parts.

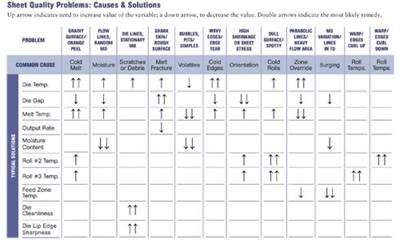

Read MoreFollow This Action Plan to Keep Your Sheet Dies in Line

Getting back into production after maintenance or troubleshooting requires a coordinated effort. Here’s how to get your sheet line up and running as fast as possible.

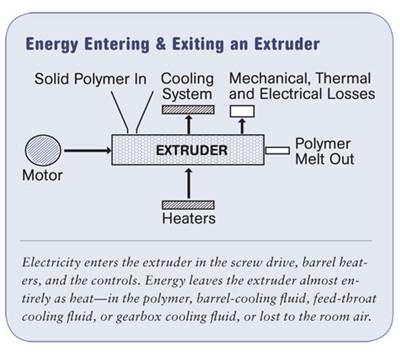

Read MoreExtrusion: Reducing Energy, Part II: ‘Adiabatic’ Extrusion

The term adiabatic extrusion was very popular in the ’60s and ’70s, but has seemingly disappeared from the processing terminology of today.

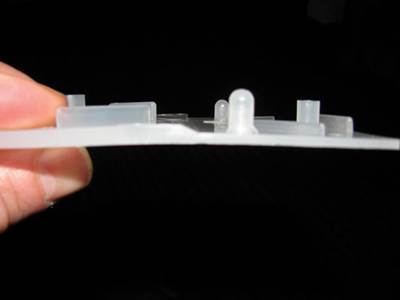

Read MoreInjection Molding: Processors: Teach Part Designers The Golden Rule

Make sure the designers you work with understand that there are limits to what processing can do.

Read MoreTooling: Setting Up Shop—Part II of III

Many repair shops in molding facilities are too small, poorly lit, and inefficiently designed.

Read MoreExtrusion: Run Your Chevy Volt with Extruder Energy Savings—Part I

The electricity saved on a large extrusion line could power a number of Chevrolet Volts.

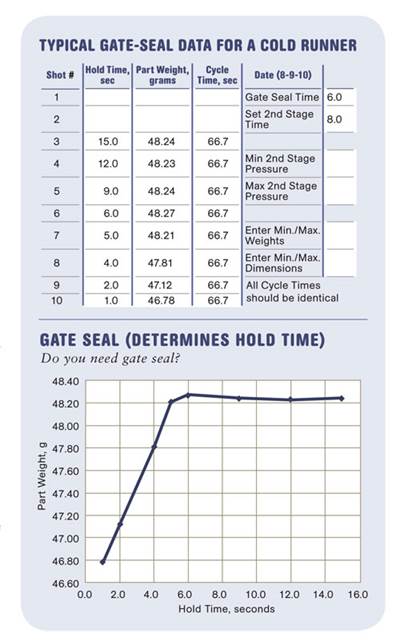

Read MoreInjection Molding: Why & How to Do Gate-Seal Experiments

Part of optimizing any molding process is determining the second-stage injection, or pack and hold, parameters.

Read More