Know-How

Extrusion: Start Up and Shut Down Properly

A key goal during startup and shutdown of the extruder is to prevent degradation of the polymer left in the extruder and downstream components such as screen changers, adapters, and dies.

Read MoreInjection Molding: Answers to Bozzelli's Drying Quiz

Three questions about drying plastics that everyone should know how to answer.

Read MoreInjection Molding: You Must Dry Hygroscopic Resins

The reason you dry certain plastics is to get the moisture out. But why does the moisture have to be taken out before processing?

Read MoreInjection Molding: Time Now for a Safety Review

For months many of us have been consumed with the Gulf oil pipeline blowout.

Read MoreTooling: Setting Up a Mold Shop: Part I

I had a toolmaker once tell me he used to slam his hand in his car door before work every morning just to get him in the right frame of mind to work in his shop.

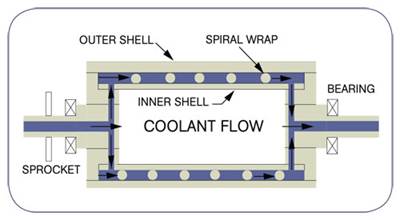

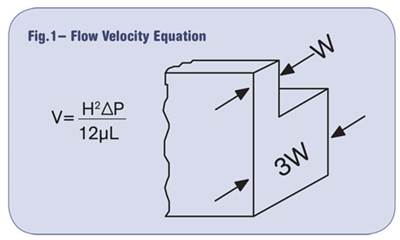

Read MoreExtrusion: Take Care of Your Rolls So They Can Play Their Role

In the sheet extrusion 大象传媒, one of your most important manufacturing assets is your cooling rolls.

Read MoreTooling: The Science of Profile Die Balancing

In our last column, we discussed the five things profile extruders need to know about profile die design鈥攑roper land length, land-length ratio, drawdown, considerations for sensitive materials, and decompression.

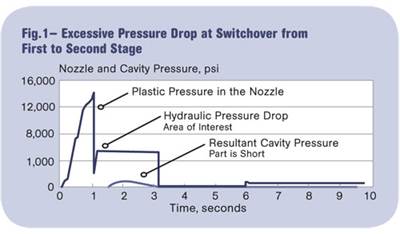

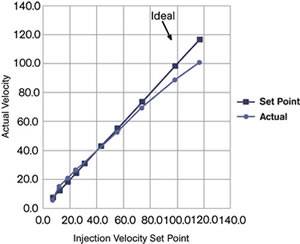

Read MoreInjection Molding: The Basics of Machine Evaluation, Part III

In the last two issues, we started defining some basic tests to ensure your injection molding machine is working properly.

Read MoreThe Basics of Machine Evaluation, Part II

Last month we started defining some basic tests to ensure your injection molding machine is working properly.

Read More