Know-How

Two-Shot Molding and Tool Design

There are a few variations of the two-shot molding process, and each has implications for tool design.

Read MoreExtruding Very High-Flow Polymers

Screw designs not suited to process lower-viscosity materials will result in poor melt quality and lower outputs.

Read MoreFaster Is Not Always Better—Optimize Your Molding Cycle

It is possible for machines to run too fast, so find the sweet spot where maximum output overlaps with good parts.

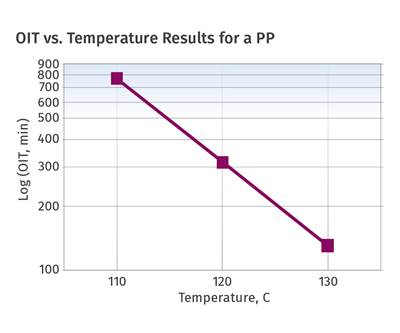

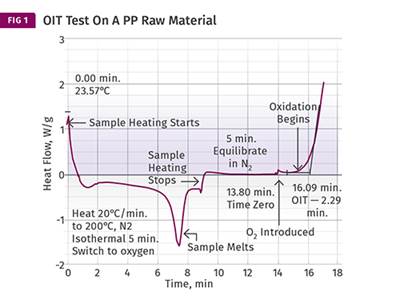

Read MoreThe Importance of Oxidative Stability in Polyolefins, Part 3

Tools and methods for determining oxidative stability can be useful, but even more useful if constructed to yield the information you really need.

Read MoreSolving Issues with Gloss

Your problem may be related to tooling, material, processing, or combinations thereof. Here’s how to find the root cause.

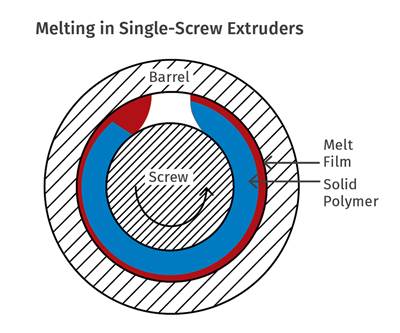

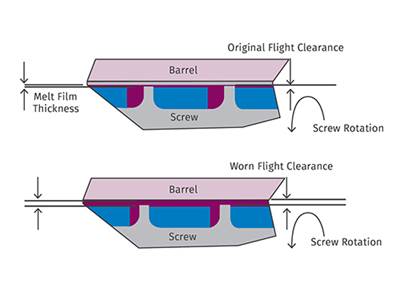

Read MoreDo You Have Screw Wear?

It’s generally caused by metal-to-metal contact, and your first indicator will be poor melt quality.

Read MoreThe Importance of Oxidative Stability In Polyolefins, Part 2

The DSC test can do a reasonably good job of capturing the comparative behavior of materials that use similar antioxidant chemistries.

Read MoreEXTRUSION: Is Head Pressure Sapping Your Extruder’s Strength?

A redesign of all of the flow paths between the end of the barrel and die may be in order.

Read MoreINJECTION MOLDING: How to Mold Living Hinges With No Flexing Required

Here are the five critical, intertwined components that must be perfected for a living hinge that doesn’t need to be flexed upon ejection.

Read More