Know-How

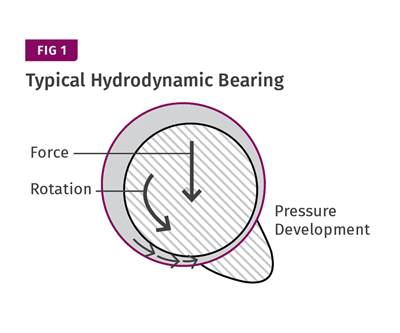

How ‘Hydro Wedges’ Reduce Screw Wear

Using them only in the melting section provides for greater design freedom and negates the impact these devices can have on output and melt temperature.

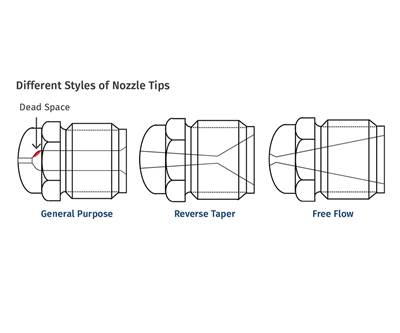

Read MoreHow to Pick, Remove, and Replace a Nozzle Tip

This small component can cause big problems. Here’s my procedure for picking and replacing yours.

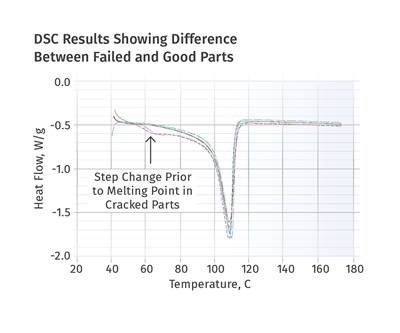

Read MoreThe Need for Generalists: Part 3

In failure analysis, there is a tendency to gravitate to a few common test protocols. But this approach can result in a mismatch of techniques to the problem.

Read More15 Things to Know About Servo-Driven Injection Machines

Drive technology for injection molding machines has been continuously evolving, and servo motors have become widely used in a variety of roles. Here’s what molders need to know about today’s servo drives in terms of cost, performance, maintenance, and training.

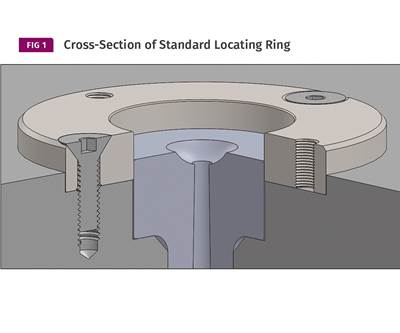

Read MoreWhat You Need to Know About Locating Rings: Part 1

Selecting the right locating ring and putting it to good use takes a lot of thought.

Read MoreExtruding with Fillers

You can use the reference point from processing unfilled polymer to determine whether you can run filled resin on your current system.

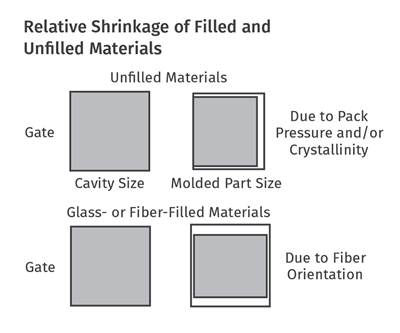

Read MoreHitting the Numbers, Part 2: The Shrinkage Factor

The shrinkage factor is one of the most critical numbers to hit.

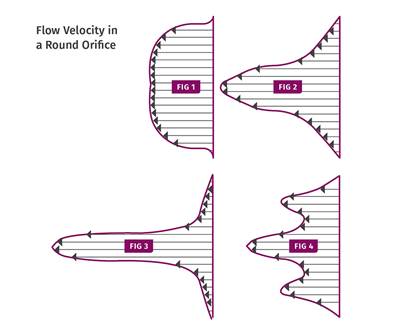

Read MoreDon’t Build In Melt-Temperature Variations

It’s not unusual for polymer to exit the extruder with a uniform melt temperature, only to be fouled up by downstream flow pipes and the like. Here’s how to avoid this.

Read MoreThe Need for Generalists, Part 2

Problem-solving requires a team that combines people having academic credentials with others who have hands-on experience.

Read MorePlastics Technology’s Most Popular Know How Columns in 2016

Temperature, pressure and time ultimately dictate plastics processing so it鈥檚 not surprising that Know How columns from industry experts on these topics are consistently among the most popular on our site.

Read More