Know-How

Injection Molding: New Mold Trial—Will It Run 24/7?

Use this nine-step process to make sure you’ll be making good parts after a successful trial. But even then, be prepared for some hiccups.

Read MoreMaterials: Cycle Time—Science vs. Rules of Thumb, Part 6

This installment—on elastomers—completes a series, whose theme is to bring more science to the discipline of molding. The overall message: Ask a lot of questions whenever someone posits this or that ‘rule of thumb’ about processing.

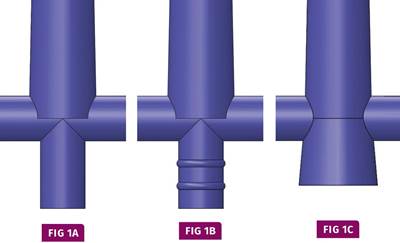

Read MoreTooling: Know the Basics of Sprue-Puller Design

Sprue-puller designs are quite varied, and there are no firm rules to follow. But here are some important cautions and caveats to keep in mind.

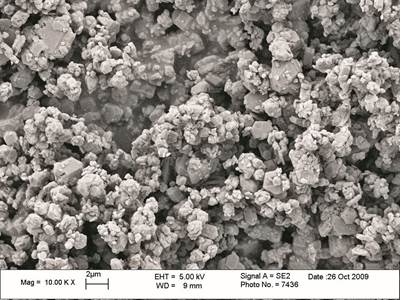

Read MoreExtrusion: The Challenges of Extruding Highly Filled Polymers

These materials require screw changes and modifications in upstream and downstream equipment and operating procedures.

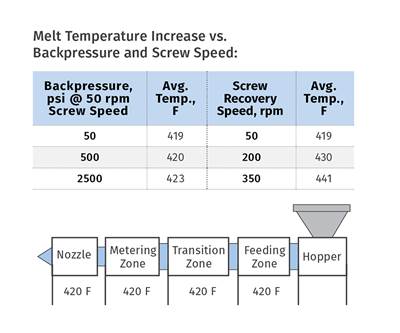

Read MoreInjection Molding: No, Backpressure Does NOT Raise Melt Temperature

It’s a classic confusion between cause and effect. Melt temperature rises when screw speed is increased. Check out this data.

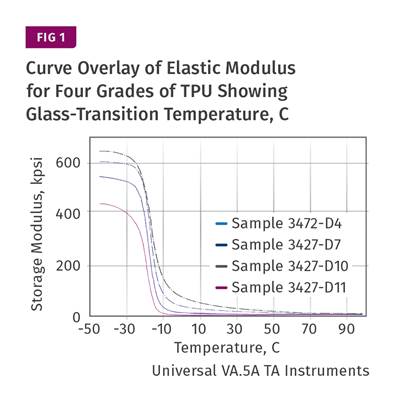

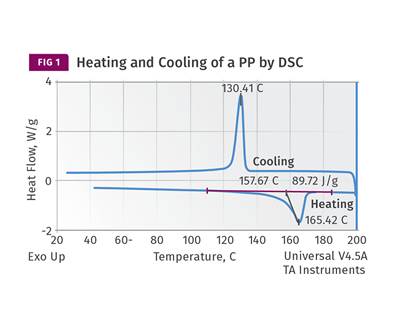

Read MoreMaterials: Cycle Time: Science vs. Rules of Thumb—Part 5

Let’s examine the behavior of semi-crystalline materials that never reach their glass-transition temperature as they cool.

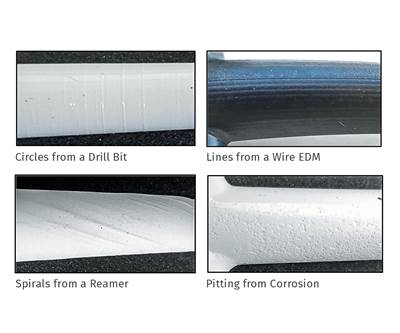

Read MoreTooling: Dealing with Sprue Bushings On the Production Floor

Causes of and solutions to some problems you probably deal with every day.

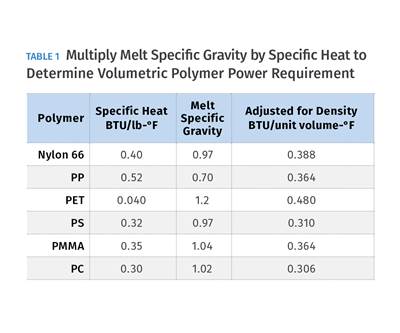

Read MoreExtrusion: The Role of Polymer Density in Screw Design

Density affects the mass flow rate, and energy transfer is based on mass, not volume. As a result, polymer density enters into practically every calculation in a screw design.

Read MoreInjection Molding: DOEs Done Right

Doing DOEs for the sake of doing them wastes time and money. But they can provide vital information to determine which process variable is determining a critical part characteristic.

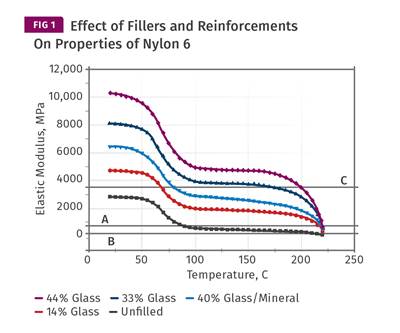

Read MoreCycle Time: Science vs. Rules of Thumb—Part 4

While laboratory tests are helpful in determining how polymers behave, you must remember the fundamental differences between laboratory measurements and the real world of plastic processing. Let’s examine semi-crystalline polymers here.

Read More