Know-How

Tricks of the Trade on RTOs and RSOs

The more you know about these runner diverters and shutoffs, the more you’ll use them. Here’s how to put them to work in your mold..

Read MorePart 11: A Processor's Most Important Job

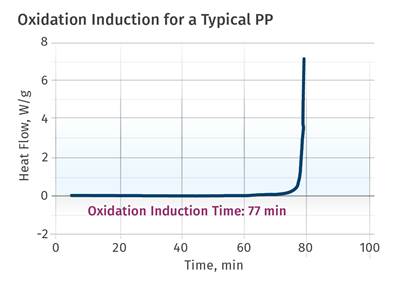

It’s the processors job to ensure molded parts contain enough stabilizer to perform to the expectations of the end use.

Read MoreIdentifying and Correcting Splay

Splay adjustments can be a simple fix, or can require several hours of babysitting a press and head scratching. Learn to find the root cause.

Read MoreA Processor’s Most Important Job, Part 10: Fiber-Length Retention

Glass and carbon fibers are often used to increase material strength and modulus. To maintain these properties, the aspect ratio of these fibers must be maintained.

Read MoreTooling: Why Ejector Pins Break and How to Prevent It, Part 3

Here we focus on forces, friction, surface finish, and lubrication.

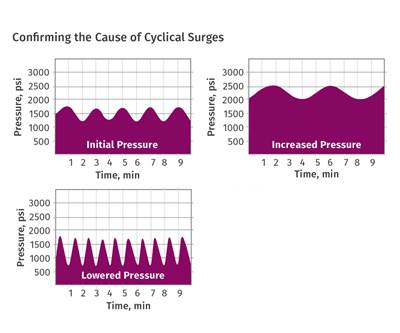

Read MoreExtrusion: Head Pressure and Output Stability

Use drag- and pressure-flow equations to analyze fluctuating output.

Read MoreInjection Molding: Sliding vs. Locking Ring—Which Non-Return Valve Is Right for You?

The locking-ring style appears to dominate the market, as most believe it makes a make a better seal and leaks less. But is this really so?

Read MoreA Processor's Most Important Job, Part 9: Avoid Molded-In Stress

How to establish molding conditions that minimize internal stress in a part.

Read MoreTooling: Why Ejector Pins Break And How to Prevent It, Part 2

Here’s the when and how to reduce the unsupported length of pins.

Read MoreInjection Molding: Is There a ‘Most-Important’ Process Parameter?

A case can be made for multiple variables—fill balance, fill time, injection pressure, cavity pressure—as most important. But there is something else altogether that is essential to successful injection molding.

Read More