Know-How

What’s With All the Static?

Static buildup on polymers can cause a variety of problems, some rather unpleasant. Yet there’s an inexpensive way to eliminate it, and we have data as proof.

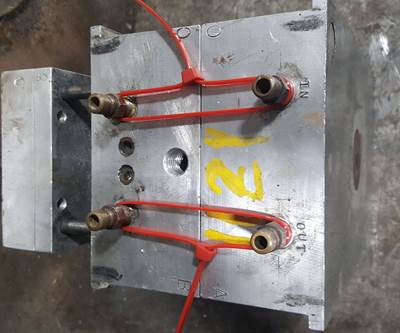

Read MoreWhat You Should Know About Injection Mold Safety Straps

Every mold should have one in order to be safe and OSHA compliant.

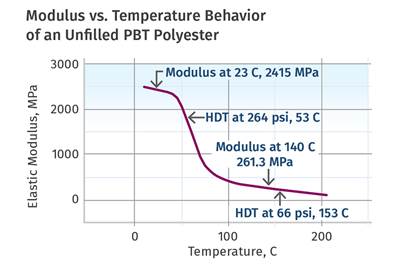

Read MorePART 2 Heat Deflection Temperature vs. Dynamic Mechanical Analysis

Here’s a real-world example of a part failure demonstrating why DMA curves have more value than single-point data generated by HDT.

Read MorePart 1: Heat Deflection Temperature vs. Dynamic Mechanical Analysis

Does the industry need a better way of reporting the temperature-dependent behavior of plastics? With DMA, it already has one. But it’s been glacially slow to catch on.

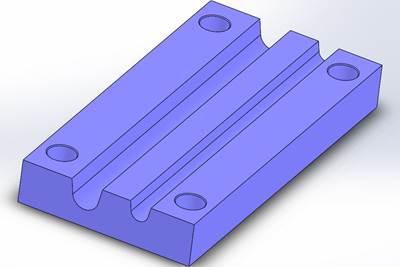

Read MorePART 2 OF 2: Tricks of the Trade on RTOs, RSOs

They have a lot more to offer molders than just shutting off a cavity. Let’s take a closer look.

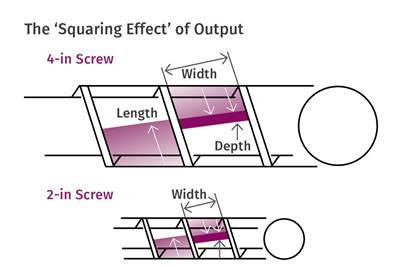

Read MoreUnraveling the Complexity of Single-Screw Scale-Up

Variables such as shear rates, melting rate, residence time and conductive heating are all influenced in the scale-up.

Read MorePART 2: The Importance of Consistent Fill Time

To make identical parts, you need to keep fill time constant. In part one we covered the why. Here’s the how.

Read MorePart 1: The Importance of Consistent Fill Time

To make identical parts, you need to keep fill time constant. Here’s why.

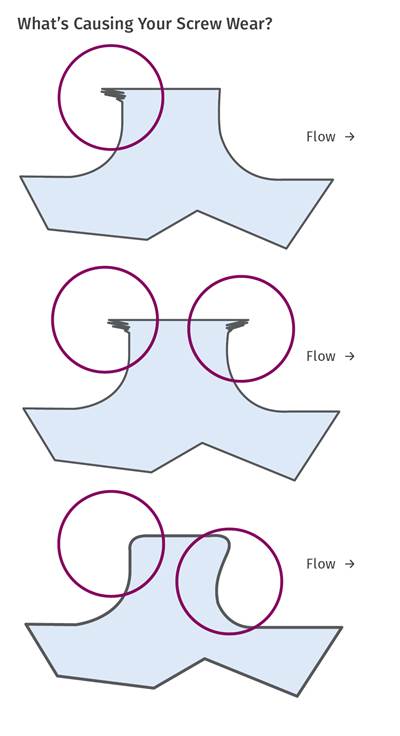

Read MoreTelltale Signs of Screw Wear

Determining the cause of wear is the first step in eliminating it.

Read MoreTricks of the Trade on RTOs and RSOs

The more you know about these runner diverters and shutoffs, the more you’ll use them. Here’s how to put them to work in your mold..

Read More