Know-How

Materials: Annealing Tips for Amorphous Polymers, Part 2

In amorphous polymers, annealing is performed to draw down the internal stresses to a level not achievable within the conditions of a normal molding process. But a few parameters are important to achieving the desired results.

Read MoreThe Cosmetic Process Window: Key to a No-Tweak, Robust Process

Establishing a process with the widest possible cosmetic window can help put your injection molding on cruise control.

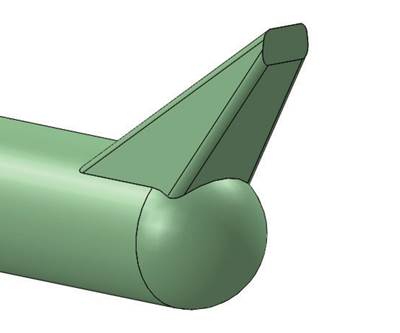

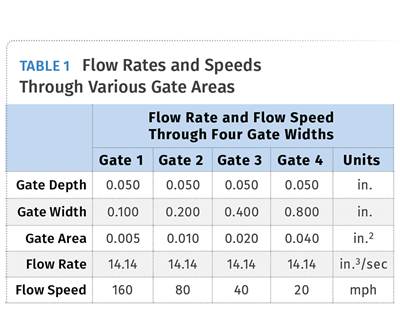

Read MoreTooling: How to Properly Size, Gates, Runners and Sprues, Part 2

Get the sprue, runner and gate sizes close to ideal the first time around.

Read MoreCompounding: Part 2 of 2 Demystifying Devolatilization

Here are some simple tools to help monitor and optimize your devolatilization process.

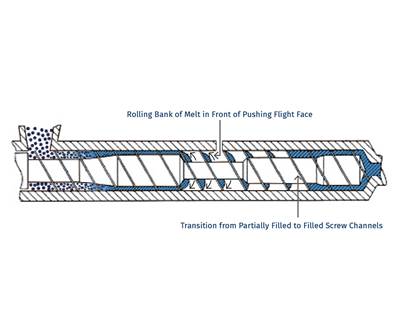

Read MoreExtrusion: Important Polymer Melting Equations for Extrusion Processors

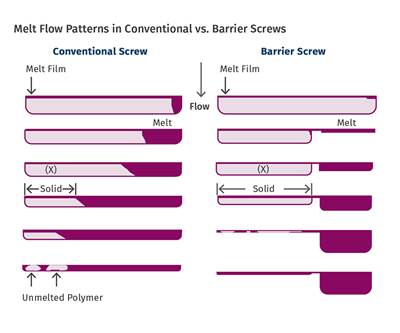

The more you know about what happens in a screw, the more you’ll be able to work with your supplier to optimize design.

Read MoreMaterials Part 1: What Annealing Can Do for Your Process

Relatively rapid cooling rates in processing introduce internal stress. If functional problems in use result, annealing may draw down the stress to levels that may not be achievable during processing.

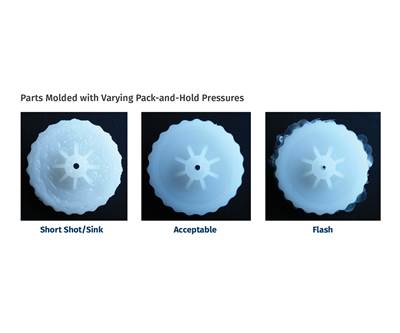

Read MoreDon’t Get Caught in the Flash-and-Shorts Chase

Injection molding’s most common defects can have inverse correlation, where correcting one causes the other, leading to the “chase.”

Read MoreFollow These Tips to Sanitize Machine Controller Screens & Buttons

Keeping your workers safe from the coronavirus makes it extremely important to institute a sanitizing procedure on all touch surfaces of the controller, screen and operating panel. I did some research and here’s what I found.

Read MorePart 1: How to Properly Size Gates, Runners and Sprues

Get the sprue, runner and gate sizes close to ideal the first time around—without spending a lot of time on extremely complicated formulas.

Read MoreTry This Lower-Cost Purging Method

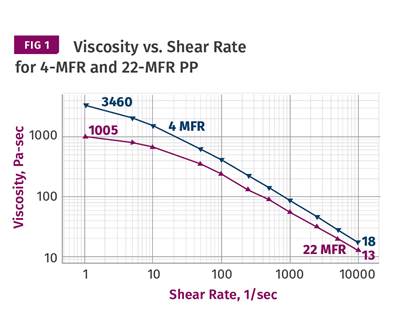

You might be able to reduce purging times and save money by scheduling processing jobs in order of the increasing material viscosity. But to get started, you'll need shear rate/viscosity curves for your polymers.

Read More