Know-How

Extrusion: Evaluating Screw Design for Multi-Material Recycling

Since many plastic products are made of a combination of materials with very different melting points, careful consideration must be given to designing screws when it comes time to recycle these products.

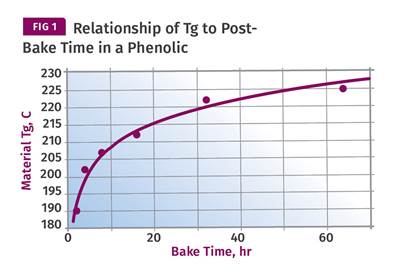

Read MoreMaterials Part 5: Annealing Tips for Crosslinked Polymers

As with semi-crystalline thermoplastics, annealing can be used in thermosetting polymers to obtain a level of crosslinking that may not be possible within the molding cycle.

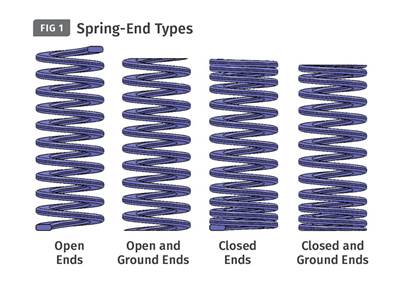

Read MoreTooling: Back to Basics on Die Springs Part 1

Some molding shops insist that all of their molds have springs to return the ejector plates. And there are lots from which to choose. Here we’ll focus on compression die springs for injection molds.

Read MoreBack to the (Re)Grind

Some amount of scrap—generated in startup, shutdown or defective parts—is inevitable. How can you reclaim regrind into new profitable parts?

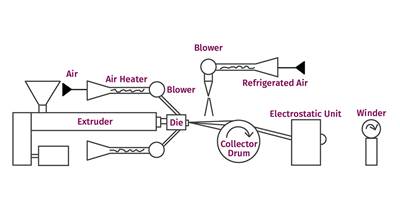

Read MoreExtrusion: 'Melt-Blown' Fiber: What You Need to Know to Enter the Face Mask Market

Coronavirus pandemic has made extrusion processors curious about entering the face-mask market. But melt-blown fiber is very different from most other extrusion processes and requires specialized equipment.

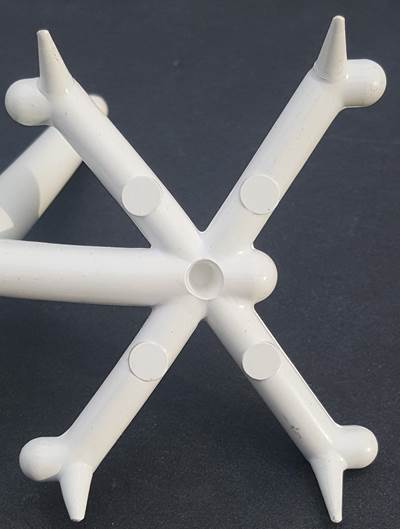

Read MoreTooling: How to Properly Size Gates, Runners and Sprues; Part 5 of 5

Get the sprue, runner and gate sizes close to ideal the first time around.

Read MoreMaterials: Annealing Tips for Semi-Crystalline Polymers: Part 4

You can forgo the elevated mold temperatures normally recommended for high-performance semi-crystalline materials. But it’s risky and likely to yield parts that under-perform expectations … assuming that they emerge from the annealing process looking anything like the drawing.

Read MoreUse This Check List to Get Your Machine Properly Installed

Whether you bought a new machine or one that’s been refurbished, you need to prepare for installation so that it can be executed as seamlessly as feasible. Here some advice.

Read MoreExtrusion: The Importance of Zone 1 Barrel Temperature

Tweaking the temperature settings of the first barrel zones may not yield the desired result. In fact, they may yield the opposite. Here’s why.

Read MoreTooling: How to Properly Size Gates, Runners and Sprues, Part 4

How to get the sprue, runner and gate sizes close to ideal the first time around.

Read More