Know-How

Considering Scaling Up for More Output? Follow These Tips

Keep these calculations handy when you are trying to decide whether a bigger extruder will get you the output you need.

Read MoreRethinking Regrind

Regrind and recycled material are often requisite in projects these days, but for many molders, the “R” word triggers painful memories.

Read MoreTracing the History of Polymeric Materials: More on Polycarbonate

The industry has learned a lot about the advantages and disadvantages of polycarbonate during its more than 60-year history, and it would be difficult to imagine a world in which it did not exist.

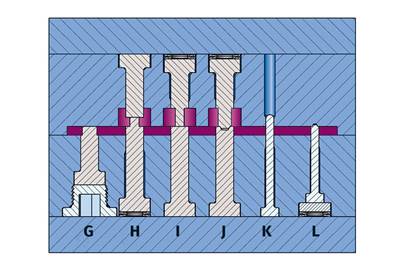

Read MoreHow to Form a Hole with a Core Pin: Part 2

Prevent wear, flash, and mold damage with these design methods.

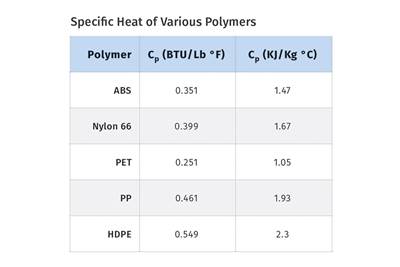

Read MoreThe Importance of Specific Heat in Screw and Extruder Design

If you ever have to size an extruder drive, knowing the specific heat of the polymer can help you to determine the capability of your equipment.

Read MoreHow to Form a Hole with a Core Pin: Part 1

Prevent wear, flash, and mold damage with these design tips.

Read MoreTracing the History of Polymeric Materials: Polycarbonate

How polycarbonate came about, virtually simultaneously, through the efforts of two industry giants.

Read More80 Questions Moldmakers Should Ask Themselves … and Their Customers

If you’re a molder or brand owner/OEM, be ready to supply the answers before the program is launched.

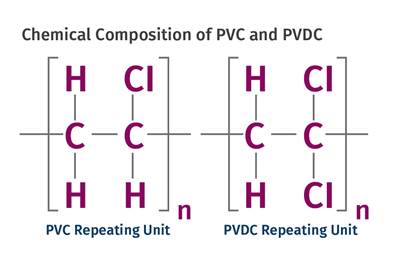

Read MoreTracing the History of Polymeric Materials: PVC & PVDC

How a class of materials based on chlorine chemistry became part of the landscape.

Read More