Know-How

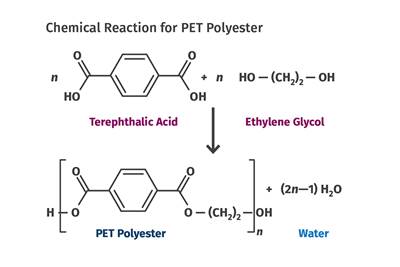

Tracing the History of Polymeric Materials: Polyesters

Beyond PET, PBT and their analogues, development of polyester chemistry led to unsaturated thermosetting resins, copolyester thermoplastic elastomers, liquid-crystal polymers and, most recently, biopolymers.

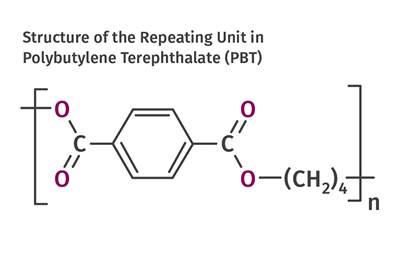

Read MoreTracing the History of Polymeric Materials: PBT

The slow crystallization of PET polyester made it a poor option for processes like injection molding. This led to the development of more molder-friendly options such as PBT.

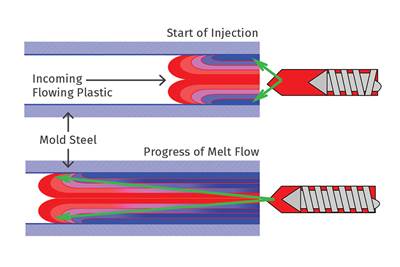

Read MoreUnderstanding Fountain Flow in Injection Molding

The phenomenon of fountain flow affects almost every aspect of the molded product — starting with filling, extending to pack and hold, and ultimately manifesting in part defects like bubbles and voids.

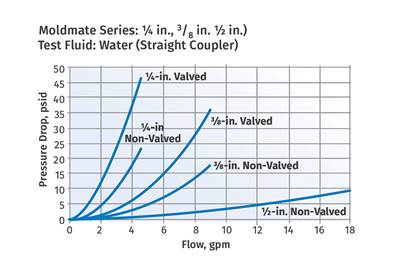

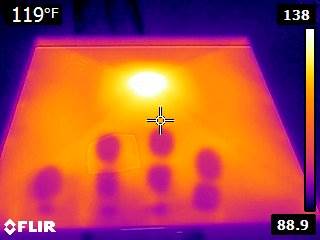

Read MoreWhat’s Controlling Your Cycle Time? Part 2

Follow these mold-cooling guidelines to maximize your profits.

Read MoreWhat’s Controlling Your Cycle Time? Part 1

Follow these guidelines to maximize your profits.

Read MoreTracing the History of Polymeric Materials: PET

How PET evolved from a material for fibers and fabrics to a force in packaging.

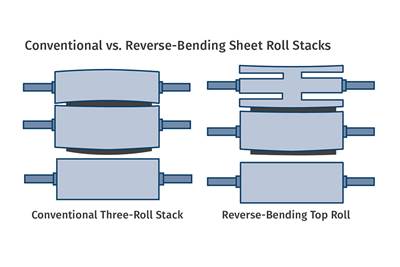

Read MoreMinimize Sheet Gauge Variation by Roll Design

‘Hour-glass’ sheet gauge can be avoided through a reverse-bending roll design that is out of patent and freely available.

Read MoreHow to Stop Melt Leakage and Carriage Blow-Back

Follow these tips when you have melt leakage around the machine nozzle and sprue bushing or injection-carriage blow-back.

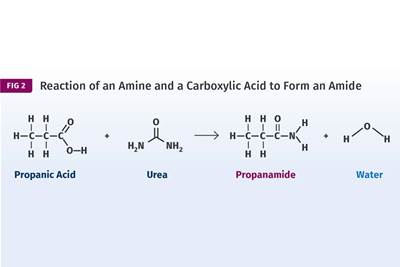

Read MoreTracing the History of Polymeric Materials: How Nylons & Polyesters Connected

The history of nylons and polyesters are intertwined, and it takes some knowledge of chemistry to understand why.

Read MoreHow Does Your Molding Machine Control Pack Pressure?

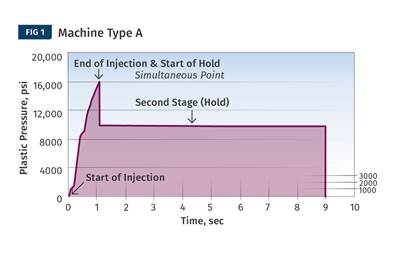

It seems some new machines have pack velocity issues, as machine builders are confusing processors with controllers that are more complicated than they need to be and less user-friendly.

Read More