Know-How

Recycling: Expanding 'Circularity' through Advanced Recycling Technologies

Recycling and achieving circularity for materials is at the core of the plastics industry’s evolving sustainable ´óĎó´«Ă˝ model. Advanced technologies will play a big role.

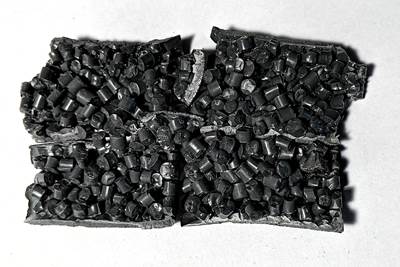

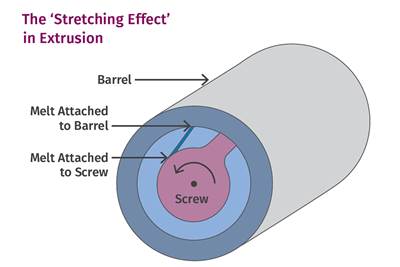

Read MoreResidence Time and Residence-Time Distribution—Part 1 of 2

Failing to calculate and accurately account for residence time can compromise material integrity before it’s even injected.

Read MoreInjection Molding: Understand the Link Between Feed Throat Temperature & Bridging

Save time and money by properly controlling the feed-throat temperature. In some cases—but not all—it can help you solve a bridging problem.

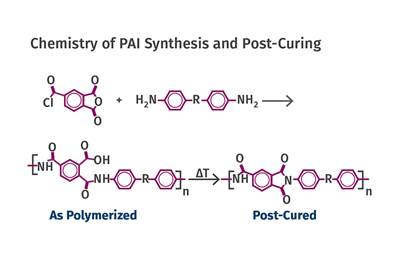

Read MoreMaterials: Annealing Tips for Polyamide-imide, Part 7 of 7

PAI is a material capable of achieving levels of performance that even semi-crystalline engineering polymers like PEEK, PPS, and PPA cannot. But you have to be willing to work for that performance, and the annealing process is an essential part of this.

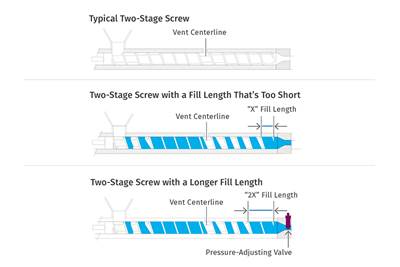

Read MoreExtrusion: Solving Surging in Two-Stage Screws

This usually crops up when the two stages are not matched in output. The best solution is to install a pressure-adjusting valve at the discharge end of the extruder.

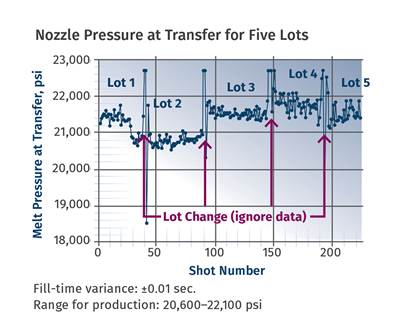

Read MoreHow to Know When Your Process is Ready to Make Acceptable Parts

Focus on six key metrics to help you determine when a process is lined out and stable enough to start production.

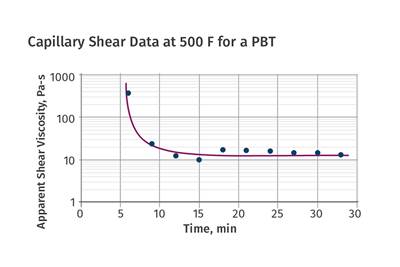

Read MoreUnderstanding the Effect of Polymer Viscosity on Melt Temperature

Every processor should get hold of the viscosity curves for the polymers they use or contemplate using in their operations, and learn how to read them.

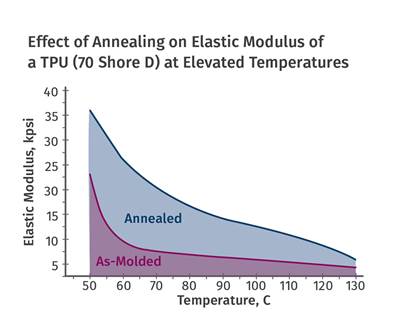

Read MoreMaterials Part 6 of 7: Annealing Tips for Thermoplastic Polyurethanes

TPUs form physical, rather than chemical, crosslinks that can be broken by reheating. Formation of these crosslinks can be sped up by annealing, which improves a variety of properties.

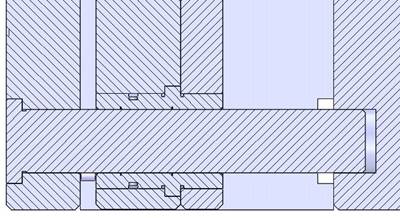

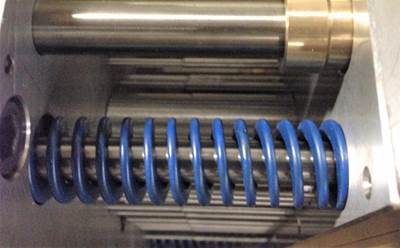

Read MoreTooling: Back to Basics On Die Springs--Part 2

Follow these steps for proper die-spring selection and installation.

Read More