Know-How

Try This Lower-Cost Purging Method

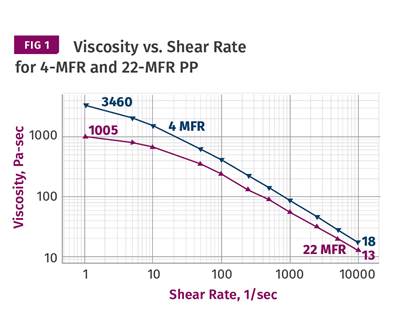

You might be able to reduce purging times and save money by scheduling processing jobs in order of the increasing material viscosity. But to get started, you'll need shear rate/viscosity curves for your polymers.

Read MoreHow to Optimize Usage of Recycled Material

Processors need to “engineer” feeding properties similar to virgin pellets into their regrind to efficiently and economically utilize more of their scrap.

Read MoreIn Search of a Universal Setup Sheet

Duplicating a process from one injection machine to another is frustrating and time-consuming. Develop a mold-specific setup sheet that works in all kinds of presses by differentiating plastic parameters from machine parameters and duplicating those plastic conditions from machine to machine, electric or hydraulic.

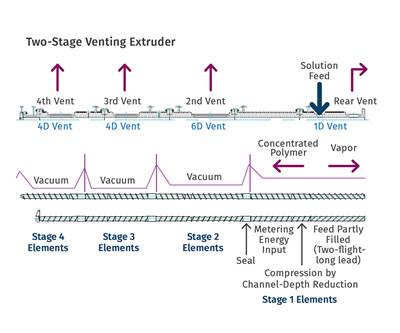

Read MoreCompounding: Part 1 of 2: Demystifying Devolatilization

Very little has been written about this critical topic, and most of what has been published is theoretical. Here’s some practical guidance to help you better understand the process and improve your operation.

Read MoreRevisiting Shot Size vs. Barrel Capacity

We’ve covered this topic before, but it’s important enough to warrant another look..

Read MoreSave Time, Money: Use a Mold-Design Checklist

Here are 15 examples of common molding issues that occur during an initial mold trial. Many of them could be avoided or corrected with a proactive checklist.

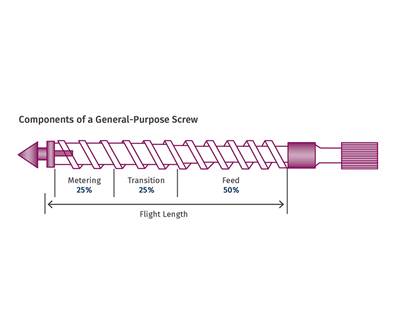

Read MoreWhat You Need to Know to Get into Coextrusion

Key considerations range from determining the right extruder sizes to tooling, matching material viscosities, and lots more. Take a look.

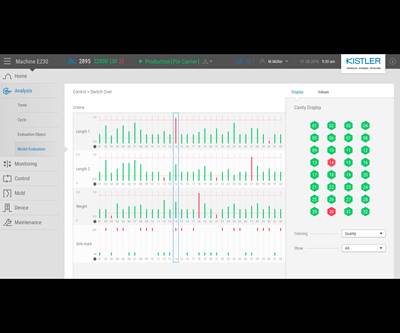

Read MoreHow Can Molders Achieve Effective Process Monitoring?

You have developed a proper process; now you need to monitor that process to ensure its stability through a run.

Read MoreHow to Prevent Nozzle Tip Leaks, Part 2

Your very costly mold in that very expensive press is relying on the performance of a $20 nozzle tip that no one ever checks, and has a high probability of not doing its job. Stop learning from your mistakes and start learning how not to make them.

Read More