Know-How

How to Deal With Residual Stress in Molded Parts

Here are design, molding, and fixturing considerations to help you handle this unavoidable issue.

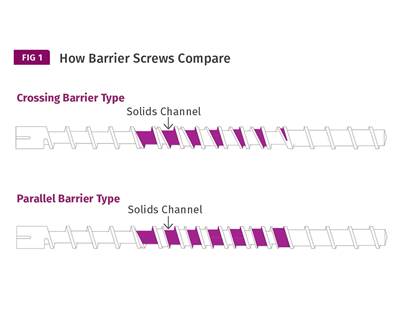

Read MoreBarrier Screws: Not All Are Created Equal

Let’s take a deep dive into parallel and crossing types and see where each fit in.

Read MoreHow to Manage Pressure Loss in Injection Molding

Achieving a process window wide enough to ensure consistent part quality depends on achieving sufficient pressure at end of fill.

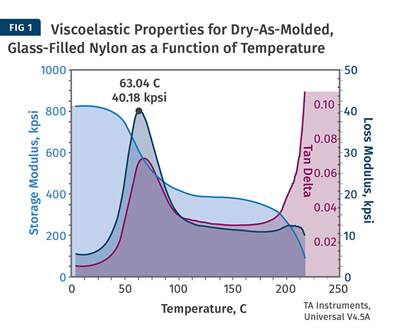

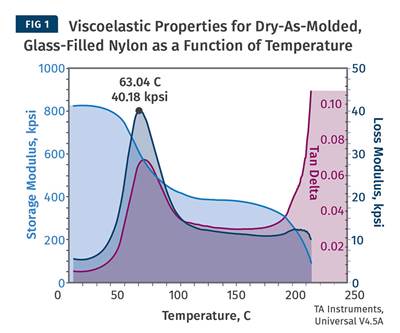

Read MorePart 5: Heat Deflection Temperature vs. Dynamic Mechanical Analysis

In the final part of this five-installment series, we bring DMA to a practical level using the results for glass-filled nylon.

Read MoreHow to Quickly Verify Your Machine & Process Setpoints

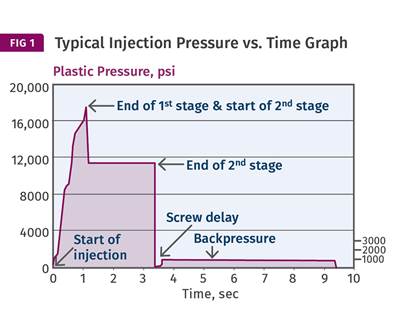

For a quick check of your process setup, the injection-pressure-vs.-time graph is your best tool.

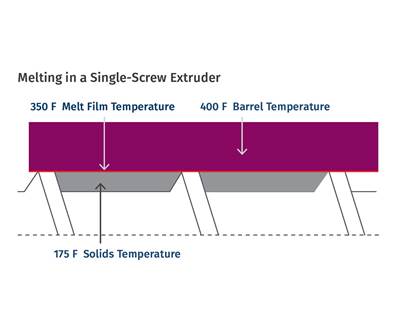

Read MoreWhy Barrel Temperatures Have a Small Effect on Melt Temperature

Extruders are not like ovens. Tweaking barrel-temperature profiles will not influence melt temperature all that much. Here’s why.

Read MoreThe 'Butterfly Effect' in Injection Molding—A Connected Process

In injection molding, a seemingly minor change in a setpoint can have a significant impact on part quality and process robustness and repeatability. That’s why Scientific Molding focuses on process outputs, not setpoints.

Read MorePart 4: Heat Deflection Temperature vs. Dynamic Mechanical Analysis

The presentation of DMA data can sometimes frustrate users and discourage its adoption. Those unfamiliar with DMA should insist on receiving data relevant to the manner in which the part they are developing will be used.

Read MoreMold-Clamping Details for Profit

Taking time to sweat the details of clamping is not much fun, but they do make a difference in a company’s bottom line.

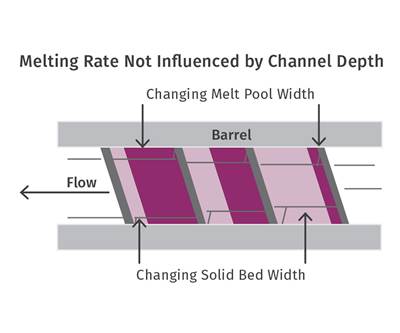

Read MoreSimple Scale-Up Calculations for Melting

You can avoid complicated melting equations when designing or evaluating a screw by using simpler methods that can save time and provide good results.

Read More