Know-How

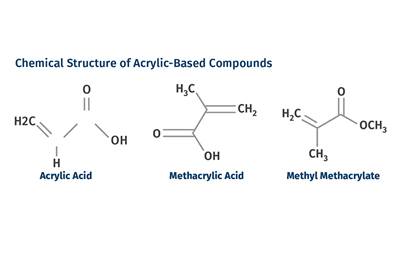

Tracing the History of Polymeric Materials: The Commercialization of Acrylic

We covered the invention of acrylic in our last installment. Here, we discuss its commercial development.

Read MoreWhat to Do About Weak Weld Lines

Weld or knit lines are perhaps the most common and difficult injection molding defect to eliminate.

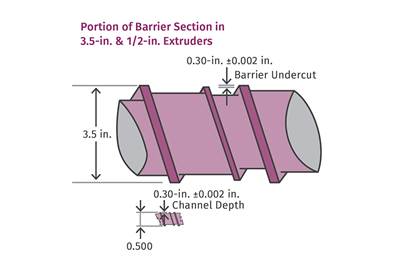

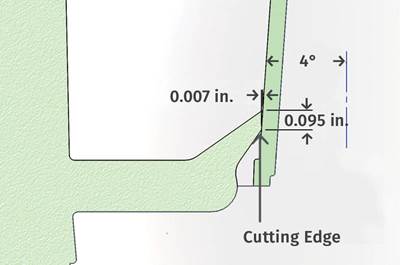

Read MoreSmaller Screws Impose Bigger Challenges

Very small extruder screws work just about like their larger cousins, but some critical differences make them harder to design and machine.

Read MoreAre Your Sprue or Parts Sticking? Here Are Some Solutions

When a sprue or part sticks, the result of trying to unstick it is often more scratches or undercuts, making the problem worse and the fix more costly. Here’s how to set up a proper procedure for this sticky wicket.

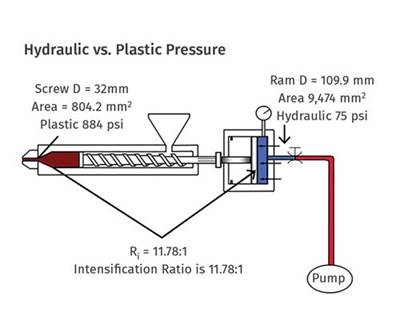

Read MoreHow to Estimate and Control Head Pressure

You rightfully worry about melt temperature, but don’t overlook head pressure, because the two are closely linked and will influence line performance.

Read MoreMelt Flow Rate Testing–Part 1

Though often criticized, MFR is a very good gauge of the relative average molecular weight of the polymer. Since molecular weight (MW) is the driving force behind performance in polymers, it turns out to be a very useful number.

Read MoreThe Scoop on Screws

The kind used as fasteners in molds, that is. Here are some design considerations to help you choose and use the right ones.

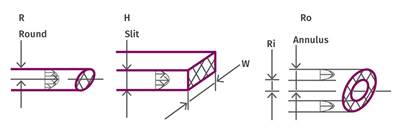

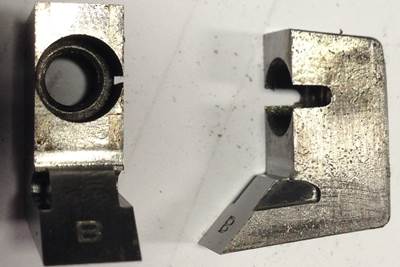

Read MoreTunnel Gates for Mold Designers, Part 1

Of all the gate types, tunnel gates are the most misunderstood. Here’s what you need to know to choose the best design for your application.

Read More