Extrusion Know How

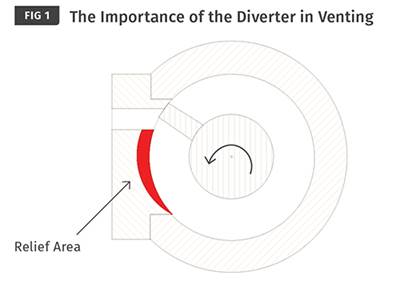

Extrusion: What’s the Best Way to Vent?

There are advantages and disadvantages to each, and they must be evaluated before making a decision.

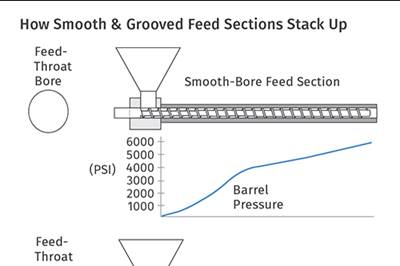

Read MoreEXTRUSION: Are Grooved-Feed Extruders Right for You?

In specific circumstances, this design can increase output and reduce melt temperature. But grooved feed throats are not for every application.

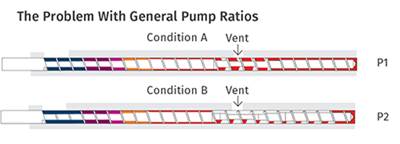

Read MoreEXTRUSION: Avoid General ‘Pump Ratios’ On Two-Stage Screws

Instead, rely on basic data and calculations to determine the proper depth of the first and second metering sections

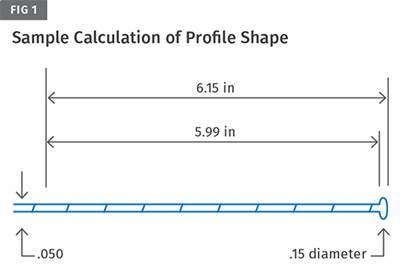

Read MoreEXTRUSION: About Your ‘General-Purpose’ Dies

There is no such thing. While dies can be adjusted to provide some flexibility, the fact is they are optimized for one specific output of one particular polymer.

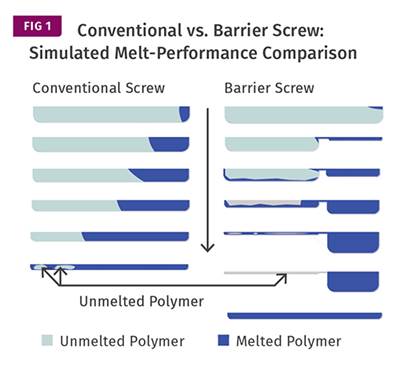

Read MoreUnderstanding Solids-Bed Breakup in Barrier Screws

Barrier screws all but eliminate problems associated with solids-bed breakup. But if they do occur, tremendous pressures can develop, causing screw wear.

Read MoreNew Extrusion Equipment Combines U.S. Management with Chinese Production

Starting up in 2011, Uway Extrusion has begun its commercial push this year, with plans to exhibit at NPE2015 next March.

Read MoreEXTRUSION: Why Bother to Chrome Plate Your Screws?

It doesn’t add that much to the overall cost and can improve performance and facilitate maintenance. So the better question is: Why not?

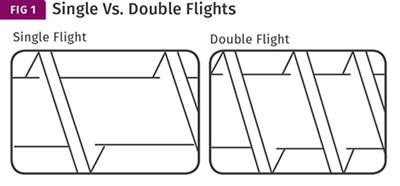

Read MoreEXTRUSION: Double Flights Are Not a Cure-All

There are certain applications where double-flighted feed sections make sense, and others where they don’t.

Read MoreEXTRUSION: Why Barrier Screws & Rigid PVC Don’t Always Mix

RPVC’s somewhat unusual melting mechanism makes it unsuited to traditional barrier type designs.

Read MoreEXTRUSION: Processing Rigid PVC? Know Your Rheology

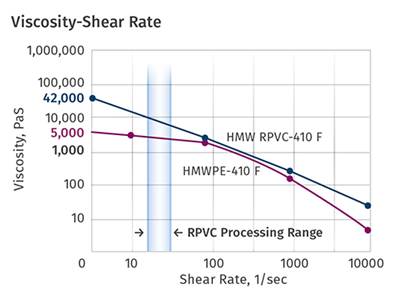

Before choosing and sizing extruders for running rigid vinyl, it is wise to bone up on the viscosity behavior of the material.

Read More