Extrusion Know How

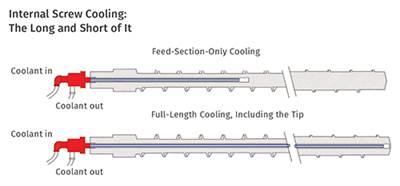

EXTRUSION: When Internal Screw Cooling Makes Sense

Internal screw cooling could help you solve solids-feeding and burning problems.

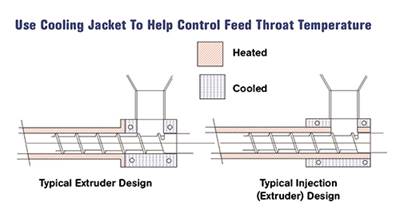

Read MoreEXTRUSION: What’s the Right Feed Throat Temperature?

Selecting the proper one is critical to the process.

Read MoreEXTRUSION: Effect of the Screw Flight On Melt Temperature, Energy Use

So-called rules of thumb regarding the design of flight clearance and width do not consider the temperature effect, both from the point of view of melt temperature and energy efficiency.

Read MoreA Better Way to Balance Die Flow

Use temperature adjustments before making any mechanical tweaks.

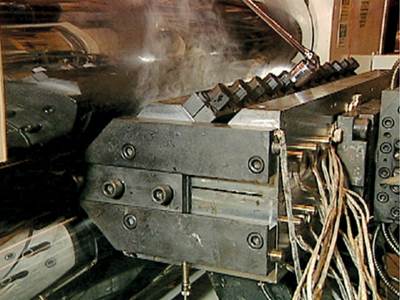

Read MoreExtruding High-Temperature Resins

Older extrusion lines might not be suitable for processing materials up to 750 F. Here's what you need to know to get started.

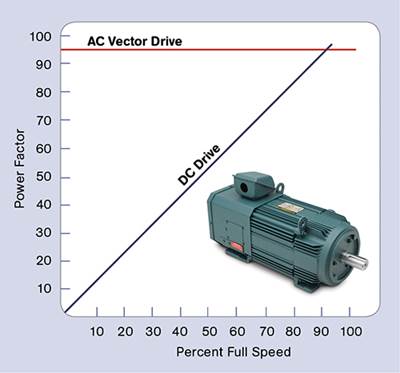

Read MoreAC Drives Take Hold

With progress in electronics and the introduction of the flux vector drive using complex control algorithms, AC drives are now equal to or better than DC drives for most applications.

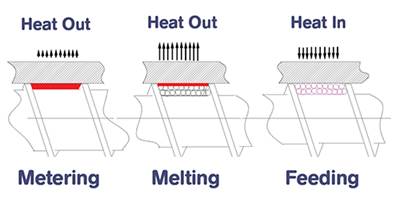

Read MoreTelltale Temperatures

Here's how to get a 'feel' for a screw design without actually seeing it. And how to use this information.

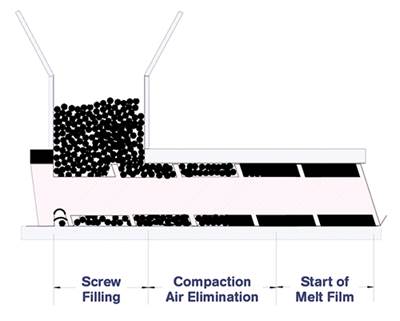

Read MoreDon’t Overlook the Feed Section

Most extrusion screw designers often do not design the feed section with the same rigor as other sections. This is odd since nothing goes through the screw that doesn鈥檛 first go through the feed section.

Read MoreRegrind and Melt Pumps

Changing levels of regrind can result in unstable output. If not set up properly, a melt pump can add to this instability鈥攖he opposite of the intended effect.

Read More