Extrusion Know How

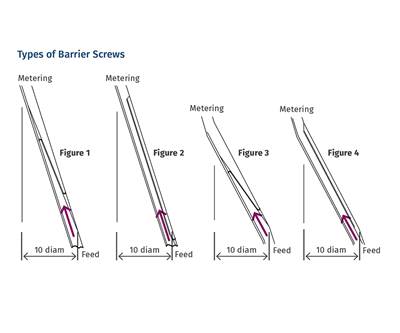

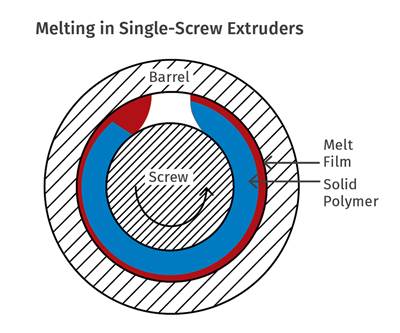

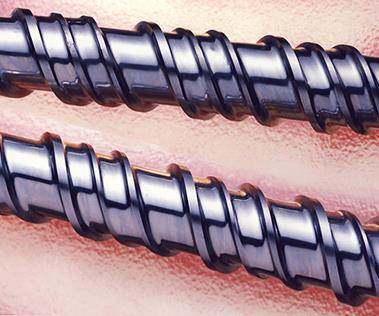

Which Barrier Screw for You?

It depends ... mostly on the melting requirements of the polymer.

Read MoreWhat Output Can I Expect?

Processors ask screw designers this question a lot. But neither output nor melt temperature can be predicted without details on the polymer and head pressure.

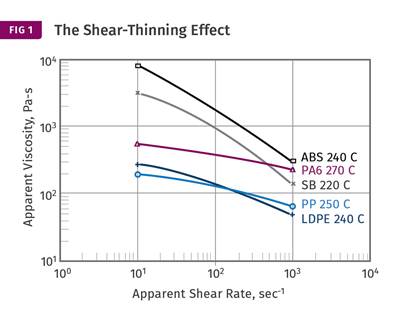

Read MoreExtruding Very High-Flow Polymers

Screw designs not suited to process lower-viscosity materials will result in poor melt quality and lower outputs.

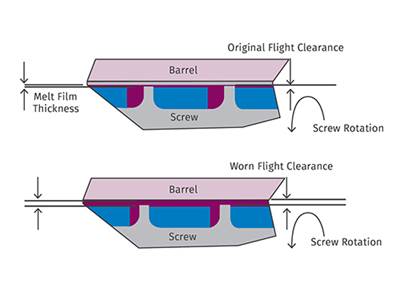

Read MoreDo You Have Screw Wear?

It’s generally caused by metal-to-metal contact, and your first indicator will be poor melt quality.

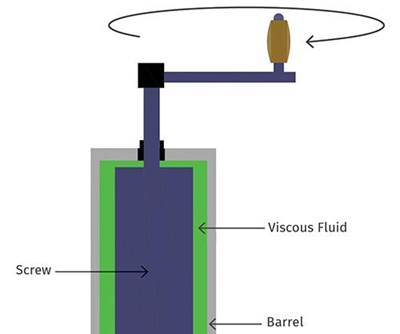

Read MoreEXTRUSION: Is Head Pressure Sapping Your Extruder’s Strength?

A redesign of all of the flow paths between the end of the barrel and die may be in order.

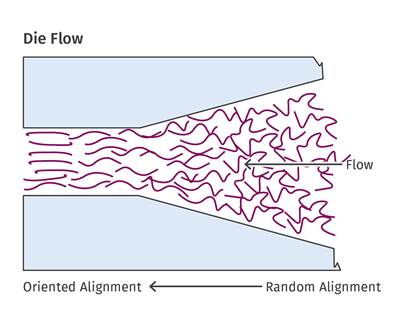

Read MoreEXTRUSION: Orientation: The Good and the Bad

Depending on what you are trying to accomplish, molecular orientation can have a positive or negative impact on your part. Here’s how to control it.

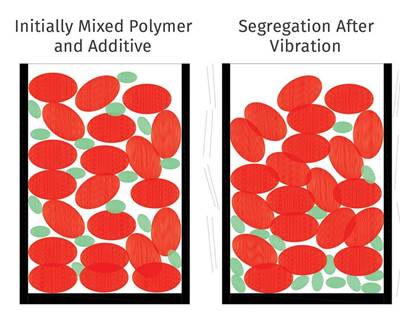

Read MoreEXTRUSION: Better Mix In Means Better Mix Out

Segregation or de-mixing of polymers and additives can be a big problem in single-screw extrusion. Here’s why it happens, and how to fix it.

Read MoreEXTRUSION: How Slow Can You Go?

Larger screws designed for high outputs will generate a variety of problems if run too slowly. Here’s why.

Read MoreEXTRUSION: Finding the Sweet Spot in Screw Design

The compression ratio of a screw does not provide enough detail on how it will perform. Screw design is a balancing act that takes many variables into account.

Read MoreEXTRUSION: Understanding The Barrier Gap

All barrier screws are not created equal, and the barrier length and gap can be one of the reasons.

Read More