Extrusion Know How

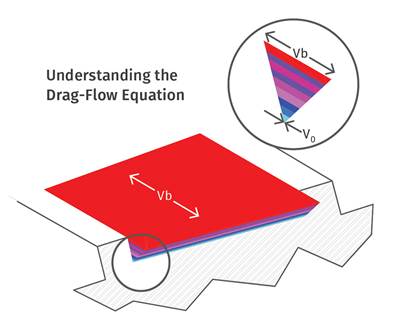

Extrusion: A Simple Way to Evaluate Extruder Screws

While there’s lots of data that influences screw design, processors usually don’t have access to it. So instead, try calculating drag flow to see if your screw is working properly.

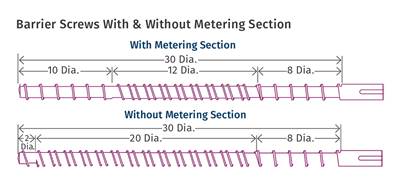

Read MoreExtrusion: Barrier Screws: Metering Section or Not?

A barrier screw without a metering section can reduce output and increase melt temperature.

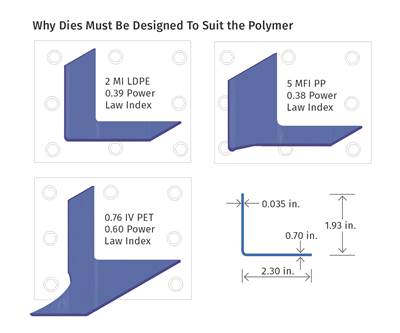

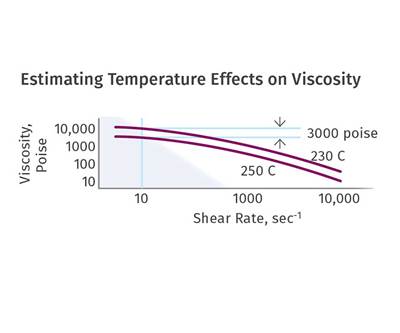

Read MoreExtrusion: Why There Are No Truly Universal Dies

Flow characteristics of different polymers vary considerably. So while adjustment features are available, for the most part dies must be designed for an individual polymer.

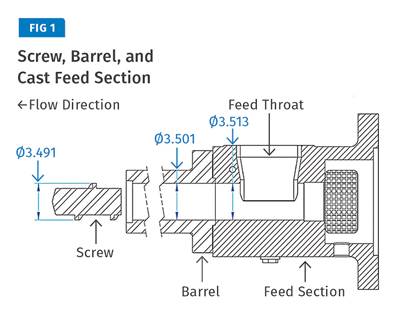

Read MoreCast vs. Integral: Which Feed Section Is Best for You?

Here are seven factors extrusion processors should weigh to help them decide between cast feed section versus an integral extrusion feed section.

Read MoreExtrusion: Understanding Weld Failures

Hard-surfacing failures without evidence of burrs indicate possible weld bond issues.

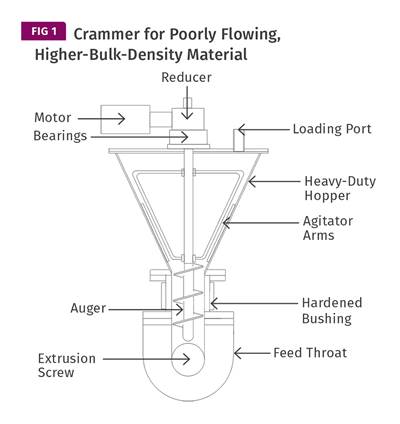

Read MoreExtrusion: How Hopper Crammers Can Help Feeding

A crammer can assist the flow of certain polymers into the extruder. But the design is not universal and very material dependent. Here’s what you need to know.

Read MoreExtrusion: The Challenges of Extruding Highly Filled Polymers

These materials require screw changes and modifications in upstream and downstream equipment and operating procedures.

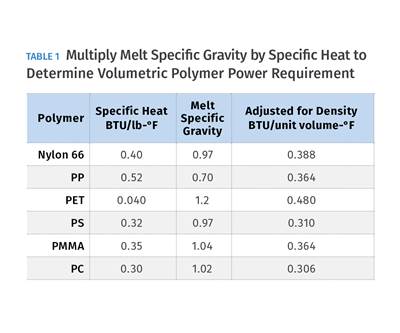

Read MoreExtrusion: The Role of Polymer Density in Screw Design

Density affects the mass flow rate, and energy transfer is based on mass, not volume. As a result, polymer density enters into practically every calculation in a screw design.

Read MoreExtrusion: The Facts About Barrel-Temperature Override

Cooling the barrel more may extract heat from the barrel, but not necessarily from the process. Here’s why.

Read MoreExtrusion: The Importance of Proper Barrel Supports

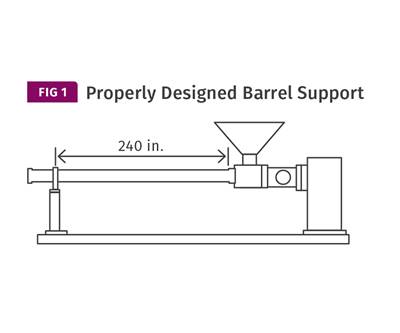

Supports that allow the barrel to expand and contract easily will prevent alignment issues. Examine them periodically for proper operation, particularly if you’re experiencing excessive wear.

Read More