Extrusion Know How

Extruding PCR? Consider a Vented Extruder

You’ll need two-stage screws to extract volatiles that post-consumer reclaim will likely contain. Screw design can be a complex balancing act. Here’s what you need to know.

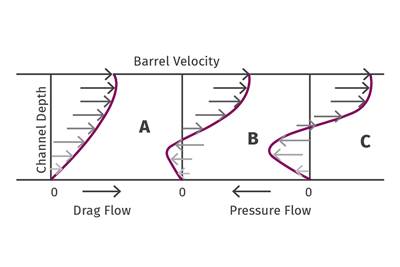

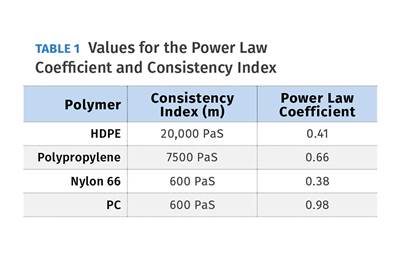

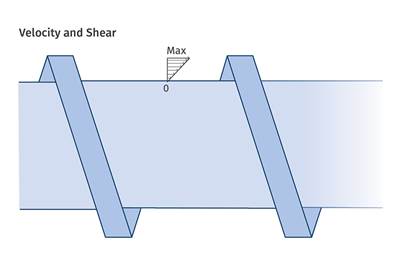

Read MoreThe Importance of Viscosity in Melting

The calculations required to determine the right melt temperature for each polymer are complicated. Knowing the power-law coefficient and the consistency index of the polymer you run might prove useful.

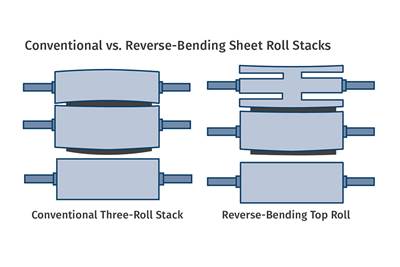

Read MoreMinimize Sheet Gauge Variation by Roll Design

‘Hour-glass’ sheet gauge can be avoided through a reverse-bending roll design that is out of patent and freely available.

Read MoreConsidering Scaling Up for More Output? Follow These Tips

Keep these calculations handy when you are trying to decide whether a bigger extruder will get you the output you need.

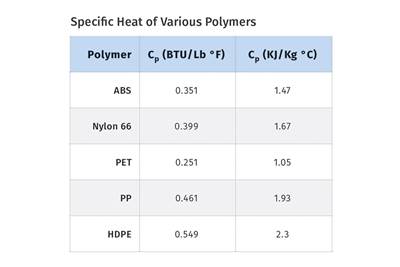

Read MoreThe Importance of Specific Heat in Screw and Extruder Design

If you ever have to size an extruder drive, knowing the specific heat of the polymer can help you to determine the capability of your equipment.

Read MoreUnderstanding the Influence of Screw Geometry on Melting Rate

They are not as closely connected as most processors think. Here’s why.

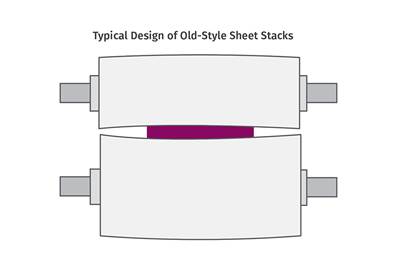

Read MoreUnderstanding Roll Deflection in Sheet Processing

Because of roll deflection, sheet stacks made for PS don’t work nearly as well with PP. One solution is to try a top roll that bends in the opposite direction.

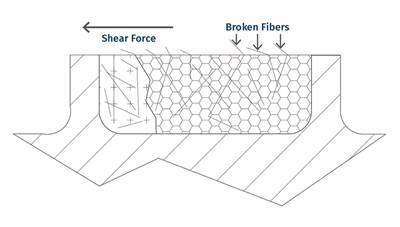

Read MorePut Science into Glass-Fiber Compounding on Single Screws

There are still companies that compound glass fibers on single screws. The process is considered an “art,” but can be made more predictable with attention to screw design, speed and length, as well the choice of mixer.

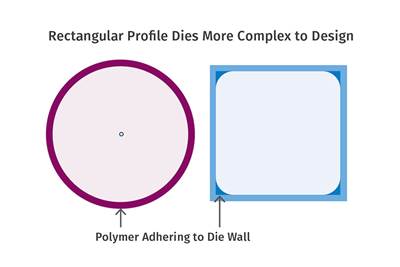

Read MoreExtrusion: Follow These Tips to Get Profile Die Design Just Right

Calculating polymer flow is fairly straightforward when designing a die for a simple round profile, but as the shapes get more complicated these calculations can get extremely challenging. Here’s what you need to consider.

Read MoreGeneral-Purpose Screws on the Comeback?

They are being specified more often for recycling applications to increase flexibility. But there is still no such thing as a GP screw and recyclers need to consider other processing approaches.

Read More