Extrusion Know How

What You Need to Know to Get into Coextrusion

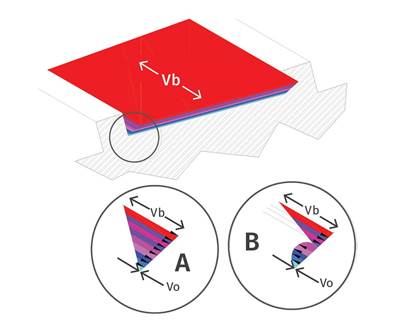

Key considerations range from determining the right extruder sizes to tooling, matching material viscosities, and lots more. Take a look.

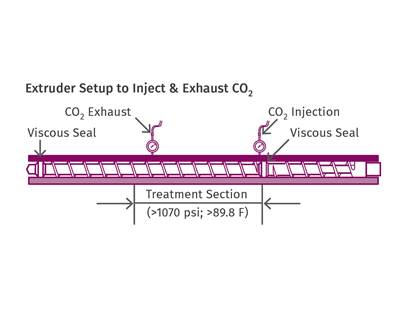

Read MoreTry This Approach to Clean Up Your Recycled Material

CO2 can be used as a totally “green” solvent to remove many kinds of contamination in recycled plastics without the need for toxic solvents.

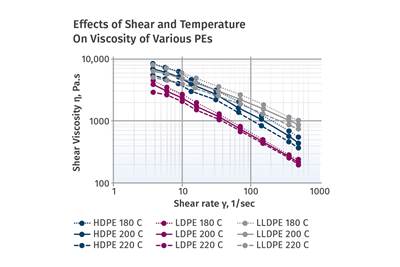

Read MoreUnderstanding Viscosity in Extrusion

Both the power-law coefficient and the consistency index must be considered to calculate viscosity.

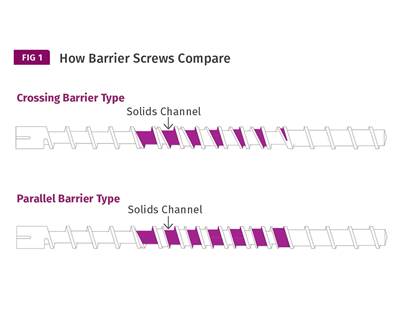

Read MoreBarrier Screws: Not All Are Created Equal

Let’s take a deep dive into parallel and crossing types and see where each fit in.

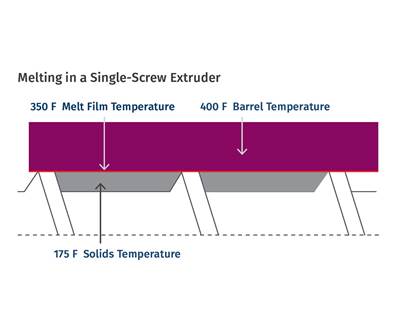

Read MoreWhy Barrel Temperatures Have a Small Effect on Melt Temperature

Extruders are not like ovens. Tweaking barrel-temperature profiles will not influence melt temperature all that much. Here’s why.

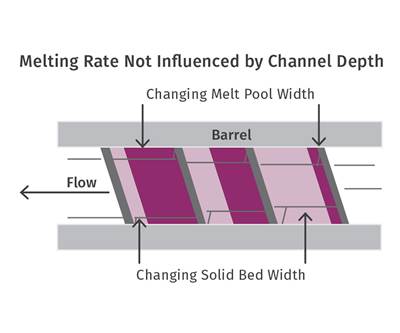

Read MoreSimple Scale-Up Calculations for Melting

You can avoid complicated melting equations when designing or evaluating a screw by using simpler methods that can save time and provide good results.

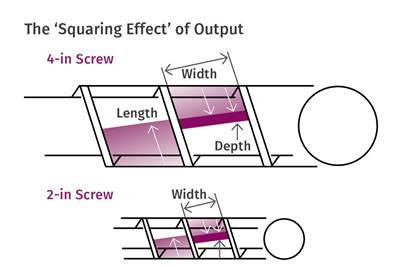

Read MoreUnraveling the Complexity of Single-Screw Scale-Up

Variables such as shear rates, melting rate, residence time and conductive heating are all influenced in the scale-up.

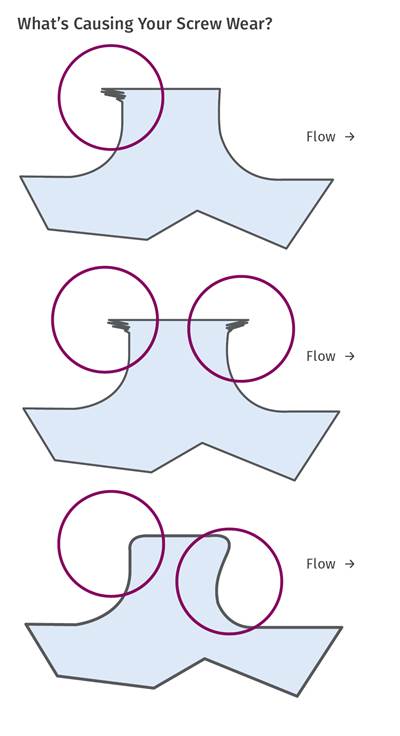

Read MoreTelltale Signs of Screw Wear

Determining the cause of wear is the first step in eliminating it.

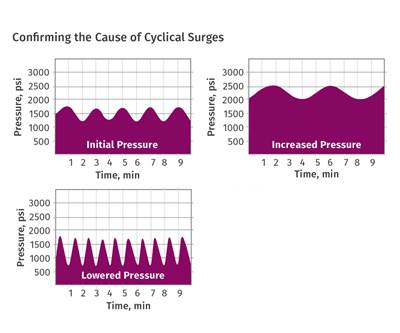

Read MoreExtrusion: Head Pressure and Output Stability

Use drag- and pressure-flow equations to analyze fluctuating output.

Read MoreExtrusion: A Simple Way to Evaluate Your Screw Performance, Part 2

A hand-held calculator and some basic equations can help determine whether your screw is up to snuff.

Read More